Global Leading Stone Processing Machine Suppliers: The China vs. Italy Debate and Your Ultimate Buyer's Guide

When sourcing stone processing equipment, buyers face a critical decision between two dominant manufacturing powerhouses that have shaped the industry for decades. The ongoing discussion about Global Leading Stone Processing Machine Suppliers inevitably centers on China versus Italy, each offering distinct advantages that appeal to different market segments and operational requirements. Understanding these differences enables informed purchasing decisions that align with specific business objectives and budget constraints.

Comparative Analysis: China vs. Italy Stone Processing Machinery

Italian Heritage: Precision Engineering and Premium Positioning

Italy's stone machinery industry represents the pinnacle of European engineering excellence, with companies like Pedrini, Breton, and Comandulli establishing global reputations for precision manufacturing and innovative technology. Italian manufacturers like Pedrini have maintained worldwide leading positions for over 50 years, while companies such as GMM, CMS/Brembana, Montresor, and Comandulli are considered industry leaders in their respective fields.

Italian manufacturers typically focus on premium market segments, emphasizing sophisticated automation, precision control systems, and advanced software integration. Their equipment often incorporates cutting-edge CNC technology with intuitive user interfaces designed for complex architectural applications requiring exceptional dimensional accuracy and surface quality.

The Italian approach prioritizes craftsmanship and engineering refinement, resulting in machines that command premium pricing but deliver superior performance in demanding applications. Italian Stone Processing Machine factory operations emphasize customization capabilities and specialized solutions for unique processing requirements that standard equipment cannot address effectively.

Service networks for Italian equipment often feature highly trained technicians and comprehensive support programs, though geographic limitations may affect response times and service costs in certain markets. Parts availability and maintenance support typically maintain high standards but often come with corresponding premium pricing structures.

Chinese Manufacturing: Scale, Innovation, and Value Engineering

China's emergence as a manufacturing powerhouse has transformed the stone processing equipment landscape through competitive pricing, rapid innovation cycles, and massive production scale. The global stone processing machine market, valued at $7.56 billion in 2022 and projected to reach $11.45 billion by 2030, reflects significant growth opportunities that Chinese manufacturers are well-positioned to capture.

Chinese manufacturers have invested heavily in advanced manufacturing technologies, quality control systems, and international certifications to compete directly with established European brands. Modern Chinese Stone Processing Machine factory operations incorporate sophisticated production equipment, automated assembly lines, and comprehensive testing procedures that ensure consistent quality output.

Cost advantages stem from manufacturing scale, supply chain integration, and competitive labor markets, enabling Chinese suppliers to offer comparable functionality at significantly reduced prices. This value proposition appeals particularly to emerging markets, small-to-medium enterprises, and operations prioritizing equipment accessibility over premium features.

Innovation cycles in Chinese manufacturing often exceed European counterparts, with rapid product development and technology integration responding quickly to evolving market demands. Chinese manufacturers frequently incorporate the latest automation technologies, IoT connectivity, and energy-efficient systems at price points that make advanced features accessible to broader market segments.

Market Positioning and Target Segments

Italian manufacturers generally target premium market segments where performance, precision, and brand prestige justify higher investment levels. Their equipment appeals to large-scale operations, architectural stone processors, and companies requiring specialized capabilities for unique applications.

Chinese manufacturers address broader market segments, from entry-level operations to sophisticated production facilities requiring advanced automation. Their diverse product portfolios enable solutions for virtually any application requirement and budget constraint, making advanced stone processing technology accessible to global markets.

Geographic preferences often influence supplier selection, with European and North American markets traditionally favoring Italian brands while Asian, African, and Latin American markets increasingly embrace Chinese alternatives. These preferences reflect varying priorities regarding initial investment costs, ongoing support requirements, and local service capabilities.

Strategic Buyer's Decision Framework

Evaluating Total Cost of Ownership

Comprehensive cost analysis extends beyond initial equipment pricing to encompass installation, training, maintenance, and operational expenses over the equipment's functional lifetime. Italian equipment typically requires higher initial investment but may provide superior durability and lower operational costs in demanding applications.

Chinese equipment offers compelling initial cost advantages that enable faster return on investment, particularly for operations with standard processing requirements. However, buyers should carefully evaluate long-term support costs, parts availability, and potential productivity differences when comparing alternatives.

Energy efficiency increasingly influences total ownership costs, especially in markets with high electricity rates or environmental regulations. Both Chinese and Italian manufacturers offer energy-efficient solutions, though specific performance characteristics may vary between brands and models.

Application-Specific Requirements

Complex architectural applications requiring exceptional precision and specialized capabilities may favor Italian solutions despite higher costs. Premium market segments demanding superior surface quality and dimensional accuracy often justify Italian equipment investments through enhanced product value and customer satisfaction.

High-volume production environments focused on cost efficiency and reliable operation may find Chinese equipment provides optimal value propositions. Standard processing applications with well-defined requirements often benefit from Chinese manufacturers' competitive pricing and rapid delivery capabilities.

Emerging market operations frequently prioritize equipment accessibility and local support capabilities over premium features, making Chinese suppliers attractive partners for market development initiatives.

Looking beyond this traditional debate, discerning buyers are discovering that the most successful manufacturers combine the best aspects of both approaches: Italian-inspired precision engineering with Chinese manufacturing efficiency and value positioning.

ShuiNan Machinery: Bridging Excellence and Accessibility

Redefining Global Leadership Standards

Among Global Leading Stone Processing Machine Suppliers, ShuiNan Machinery has emerged as a compelling alternative that challenges conventional China-versus-Italy assumptions. Established in 1997, the company demonstrates how Chinese manufacturers can achieve international recognition through systematic focus on quality, innovation, and customer satisfaction.

ShuiNan's 60,000 square meter facility incorporates advanced European manufacturing equipment alongside proprietary production technologies, creating a hybrid approach that delivers Italian-level quality at Chinese pricing structures. This strategic positioning enables the company to serve premium market segments while maintaining accessibility for diverse customer requirements.

International certifications including ISO9001:2015, CE, and TUV demonstrate commitment to global quality standards that match or exceed those maintained by established European competitors. These certifications validate manufacturing processes and quality control systems that ensure consistent performance across diverse applications and operating environments.

Comprehensive Solutions Portfolio

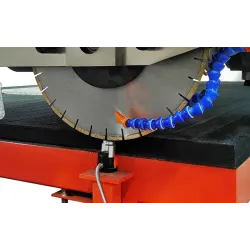

ShuiNan's product range addresses the complete spectrum of stone processing applications, from basic cutting operations to sophisticated CNC-controlled systems requiring exceptional precision. Bridge cutting machines deliver reliable performance for standard applications, while advanced automated systems provide capabilities comparable to premium Italian alternatives.

The company's best Stone Processing Machine solutions incorporate advanced features including precision control systems, automated material handling, and integrated quality monitoring that traditionally characterized high-end European equipment. However, Chinese manufacturing efficiency enables these advanced capabilities at price points accessible to broader market segments.

Multi-functional processing centers combine cutting, polishing, and finishing operations within integrated platforms that optimize workflow efficiency while reducing facility space requirements. This comprehensive approach provides superior value propositions for operations requiring diverse processing capabilities.

Customization capabilities enable specialized solutions for unique application requirements, demonstrating engineering flexibility that addresses complex customer needs without the premium pricing typically associated with custom European equipment.

Global Market Validation

International market presence across more than 30 countries provides objective validation of equipment performance and customer satisfaction in diverse operating environments. This geographic diversity demonstrates adaptability to varying regulatory requirements, environmental conditions, and application demands that validate supplier reliability.

European market penetration particularly validates quality standards and performance capabilities, as these demanding markets maintain strict requirements for industrial equipment. Successful competition with established Italian brands in European markets demonstrates ShuiNan's achievement of truly global quality standards.

Customer retention rates and repeat business levels indicate consistent satisfaction with equipment performance and service quality over extended operational periods. High retention rates suggest reliable delivery of promised performance and service levels that justify customer loyalty despite competitive alternatives.

Technical support networks spanning multiple continents ensure responsive customer service regardless of geographic location, addressing traditional concerns about Chinese manufacturers' international support capabilities. Comprehensive training programs and ongoing technical assistance facilitate successful equipment implementation and optimization.

ShuiNan Machinery's success demonstrates how forward-thinking manufacturers can transcend traditional geographic stereotypes by combining the best aspects of global manufacturing excellence. Their approach offers buyers compelling alternatives that challenge conventional assumptions about China-versus-Italy equipment selection decisions.

Discover how ShuiNan Machinery's innovative approach to stone processing solutions can optimize your operations by exploring their comprehensive product portfolio at https://shuinanmachinery.com/.

Leave a Comment