Bridge Multiblade Block Cutter: A Practical Buyer’s Guide for Granite & Marble (2000–3000mm, Up to 17 Blades)

If you run a stone factory in the Middle East, Africa, or Central Asia, your block cutting stage decides your daily slab output, labor needs, and downstream polishing efficiency. This guide explains how a bridge-type multiblade block cutting machine works, what specifications actually matter, and how to choose the right configuration for your material and production target.

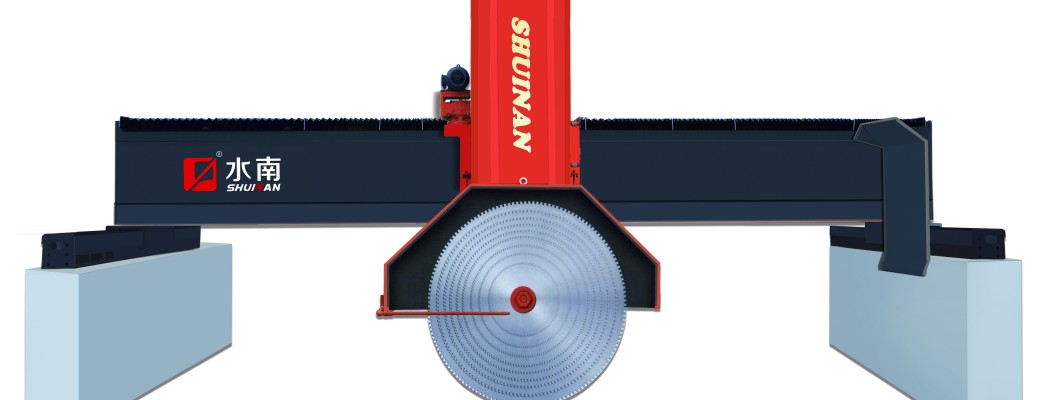

What Is a Bridge Multiblade Block Cutter?

A bridge multiblade block cutter (also called a bridge-type multi blades block cutting machine) is designed to cut stone blocks into slabs using multiple circular blades mounted on one spindle. Compared with single-blade cutting, multiblade cutting can increase throughput by processing more kerfs per pass.

For granite and marble plants, it is typically used for high-volume slab production where stable thickness, clean surfaces, and repeatable output are critical.

Why Multiblade Matters in the Middle East, Africa, and Central Asia

- Higher daily slab output: more blades can mean more slabs per cutting cycle, depending on material hardness and power setup.

- More stable unit cost: when output rises, your cost per square meter can drop—especially where labor and uptime are key constraints.

- Better planning for downstream lines: consistent slab thickness helps calibrating, polishing, and resin processes run smoother.

- Adaptable to local conditions: robust mechanical structure and practical maintenance design are important for regions with long spare-part lead times.

Key Specifications Buyers Should Compare

Below are the specs that usually determine real-world performance and suitability (not just brochure numbers).

1) Blade Diameter: 2000–3000mm

Blade diameter affects cutting depth, stability, and the machine’s structural requirements. If you process mixed block sizes or want more flexibility, choosing within the 2000–3000mm range helps you match different production needs.

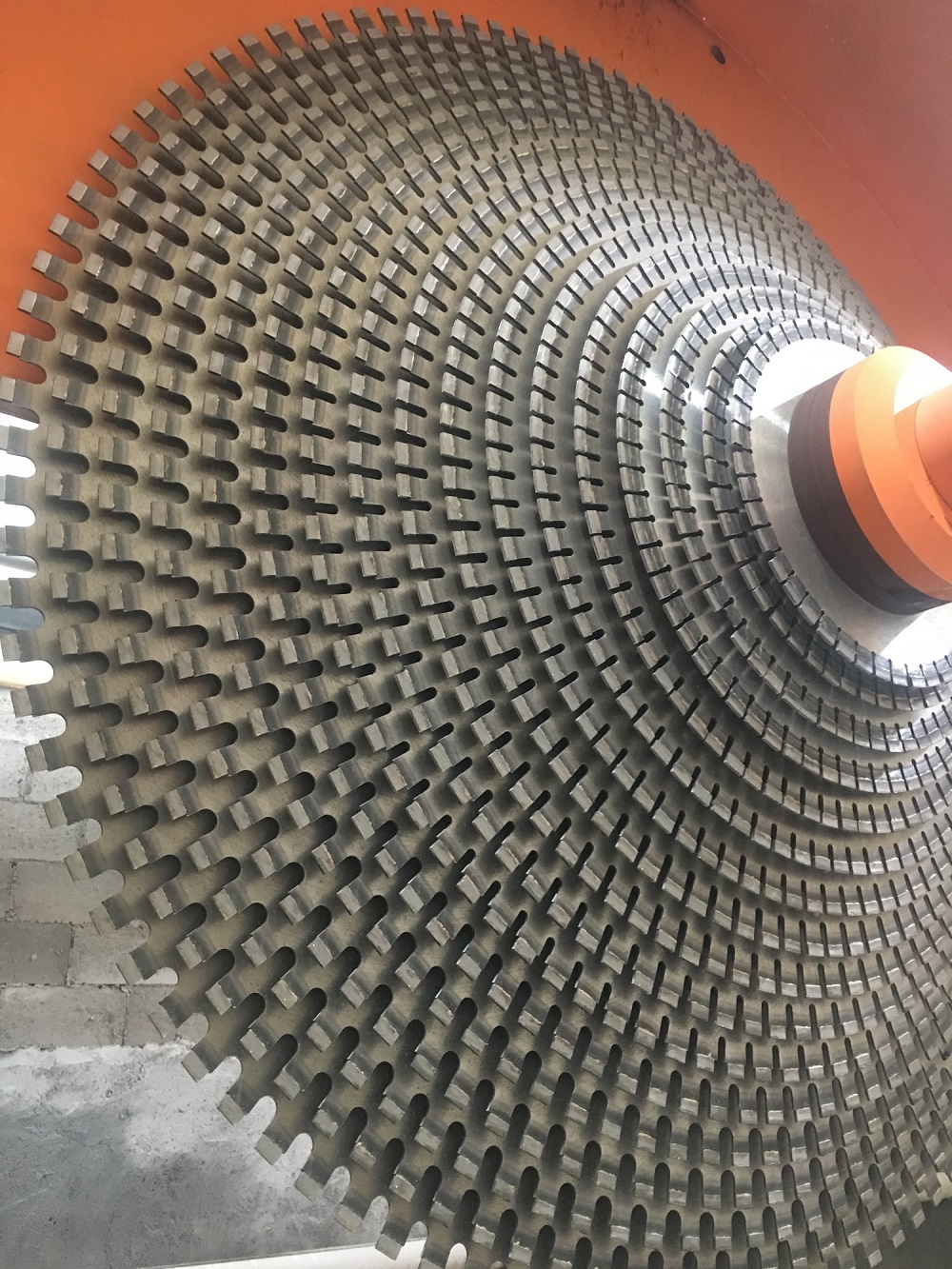

2) Number of Blades: Up to 17 Blades

More blades can increase throughput, but only if the rest of the system supports it:

- Main motor power and torque for hard stones (especially granite and some engineered stones)

- Cooling and water flow to each blade for stable cutting and blade life

- Spindle rigidity and balance to reduce vibration and keep thickness consistent

- Feeding stability (rails, guides, and lifting system) to prevent tapering

A good supplier should help you decide whether you need the maximum blade count, or a configuration that gives better stability and lower operating risk.

3) Maximum Block Size: 3m × 2m

Your maximum block size sets your baseline for travel, lifting stroke, and table/support structure. For a max block size of 3m × 2m, confirm:

- Working table dimensions and loading method

- Maximum cutting height and safe clearance

- Machine foundation requirements for long-term alignment

4) Structure and Lifting/Feeding System

In multiblade cutting, vibration control is everything. Ask about the bridge structure, guide rails, and the lifting/feeding design that keeps the spindle path stable. A well-built structure improves slab thickness consistency and reduces blade wear.

5) Water, Slurry, and Workshop Readiness

Many factories underestimate water and slurry management. For smooth operation, confirm:

- Recommended water flow and pressure

- Slurry discharge direction and collection design

- Compatible settling/filtration options to reduce pump and nozzle problems

How to Choose the Right Configuration (Simple Checklist)

- Material type: granite, marble, limestone, basalt, etc. Harder stones require stronger power and cooling margins.

- Block size distribution: average vs maximum (up to 3m × 2m). Choose blade diameter and travel based on your real block sizes.

- Target slab thickness: thickness stability depends on rigidity, vibration control, and correct parameters.

- Daily output target: decide blade count based on sustainable output, not only maximum blades.

- Local support plan: confirm spare parts list, remote support, and recommended on-site stock for fast recovery.

Common Problems and Practical Solutions

Problem 1: Uneven slab thickness or taper

- Check guide rail alignment and feeding stability

- Reduce vibration (blade condition, spindle balance, cutting parameters)

- Verify foundation level and long-term settling

Problem 2: Chipping on edges (especially granite)

- Optimize feed speed and cooling

- Check blade quality and segment suitability

- Ensure stable clamping/support for the block

Problem 3: Low output compared to expectation

- Confirm whether the blade count matches power and stone hardness

- Review cycle time: loading, setup, cutting, unloading, and cleaning

- Improve water/slurry flow to prevent overheating and forced slow-down

FAQs (Middle East / Africa / Central Asia Buyers)

Can one machine cut both granite and marble blocks?

Yes, but the best setup depends on hardness, blade segments, cooling, and stable parameters. Share your stone types and we can recommend a practical configuration.

Is “up to 17 blades” always the best choice?

Not always. The best choice balances output with stability, power margin, and maintenance. In some factories, a slightly lower blade count delivers better consistency and uptime.

Which blade diameter should I choose: 2000mm or 3000mm?

Choose based on your real block height and cutting requirements. If you process larger blocks regularly, a larger diameter can offer more cutting depth. If you have mixed sizes, a flexible plan across 2000–3000mm may be ideal.

What information should I prepare to get an accurate recommendation?

- Stone type(s) and hardness

- Block size range (average and max up to 3m × 2m)

- Target slab thickness and daily output goal

- Local voltage / frequency and workshop layout constraints

Why Choose Shuinan Machinery

Shuinan Machinery focuses on stone processing equipment with practical configurations for international markets. For block cutting, we support multiblade bridge solutions with:

- Blade diameter options from 2000mm to 3000mm

- Up to 17 blades configuration

- Support for large blocks up to 3m × 2m

- Export-ready documentation, remote technical support, and spare-part guidance

Leave a Comment