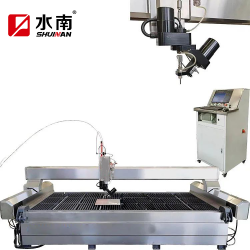

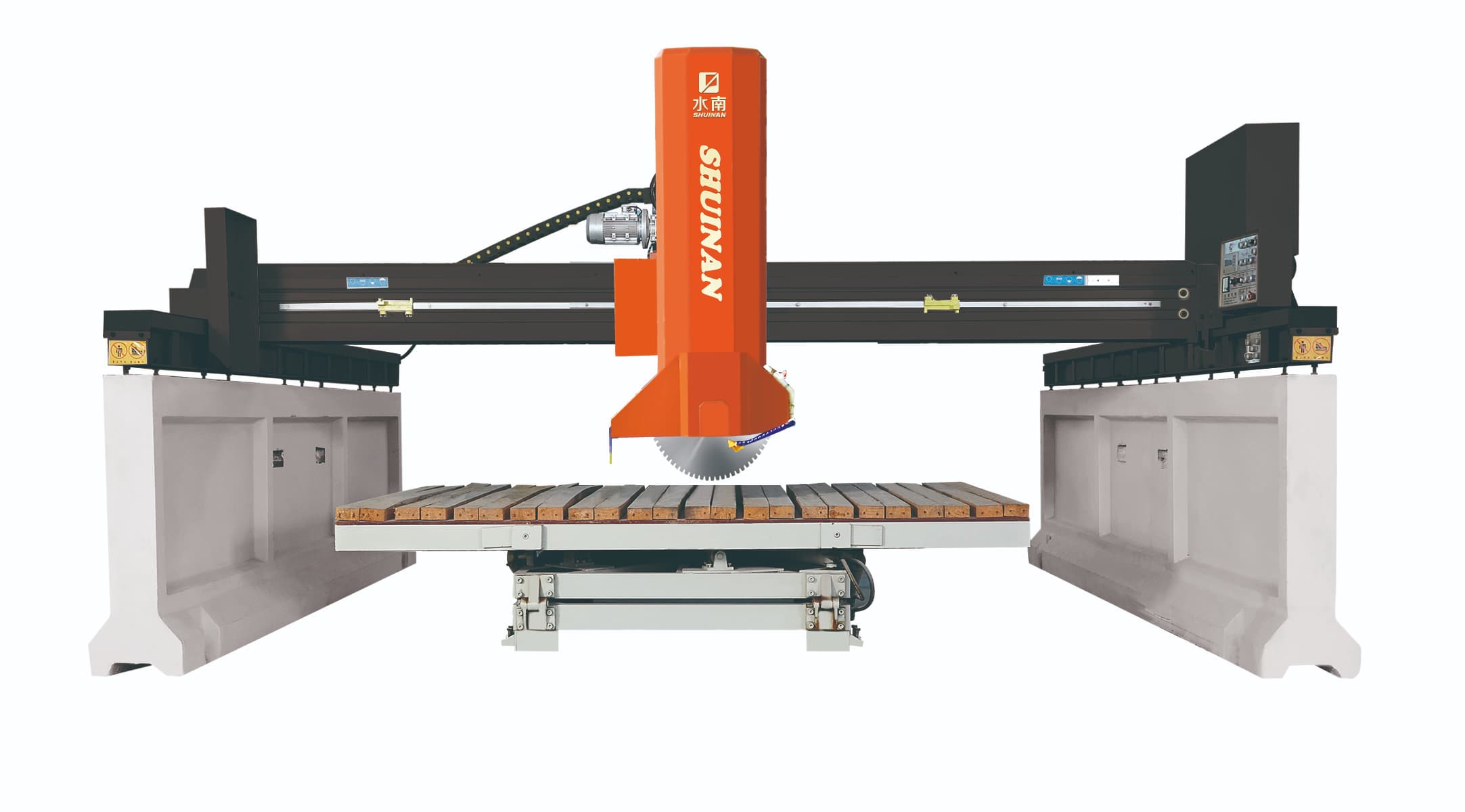

Advanced Factory Industrial Machinery - Stone Tile Cutter for Marble & Granite Processing

Our stone tile cutting machine is engineered for quarry owners, stone factory processing, industrial-scale mining operations, and equipment distributors, not household or DIY use. With ±0.5 mm precision and 120–150 m²/day capacity, it's built for large-scale production environments.

Technical Specifications

| Parameter | Value | Unit |

|---|---|---|

| Overall dimension | 6000x5000x3000 | mm |

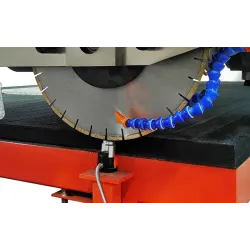

| Diameter of blade | 600 | mm |

| Max working dimension(LxWxH) | 3200x2000x80 | mm |

| Processing thickness | 180 | mm |

| Power of main-drive | 18.5 | kw |

| Table dimension(LxW) | 3000x2000 | mm |

| Table horizontal rotation degree | 360° | deg |

| Table tilting degree | 0-85° | deg |

| Water consumption | 4.5 | m³/h |

| Approximate weight | 5800 | kg |

Performance Data

| Parameter | Value | Unit |

|---|---|---|

| Daily Output | 80-100 | m²/day |

| Power Consumption | 32 | kWh/day |

| Water Consumption | 20 | m³/day |

Note: Our premium tile cutter is engineered specifically for stone factories and large-scale stone processing for natural stone, marble, and granite tiles, delivering exceptional precision and efficiency.

Water Recycling: Our stone tile cutter features an integrated water recycling system that reduces water consumption by up to 70%.

Ready to Upgrade Your Stone Tile Cutting Capabilities?

Why Our Stone Tile Cutter Stands Above the Rest

Global Industry Leader

Trusted by stone fabricators in 50+ countries for our superior natural stone tile cutters

Certified Excellence

ISO and CE certified tile cutting machines that exceed international quality standards

Innovative Technology

Patented cutting system delivers superior results for marble and granite tile processing

Unmatched Precision

Our stone tile cutters achieve industry-leading ±0.5mm cutting accuracy

Comprehensive Support

24/7 technical assistance and rapid spare parts delivery for your tile cutter

Maximum ROI

Energy-efficient tile cutting machines with low maintenance costs and high productivity

Frequently Asked Questions

What types of tiles can your machine cut?

Our tile cutting machine is specially designed for cutting natural stone, marble, and granite with high precision and efficiency. It can also cut ceramic tiles, but this is not recommended. The machine uses infrared assistance for enhanced accuracy.

Can your tile cutter handle large-format stone tiles?

Yes, our stone tile cutting machine is designed to handle tiles of unlimited length thanks to its sliding table system. The standard table width accommodates tiles up to 800mm wide, and we offer extended table options for larger formats. The cutting depth of 110mm allows for processing thick natural stone slabs as well.

What maintenance is required for your tile cutting machines?

Our marble and granite tile cutters are designed for minimal maintenance. We recommend daily cleaning of the water system, weekly lubrication of moving parts, and monthly inspection of the blade and motor. With proper care, our machines typically operate for 5+ years before requiring any major component replacement.

Do you provide training for operating the stone tile cutter?

Yes, we provide comprehensive training for all our natural stone tile cutters. This includes on-site installation, operator training, maintenance procedures, and troubleshooting guidance. We also offer remote video training and have detailed operation manuals available in multiple languages.

What is the lead time for delivery of your tile cutting machines?

Standard models of our stone tile cutters are typically available within 2-3 weeks. For customized machines, the lead time is 4-6 weeks. We ship worldwide with door-to-door delivery service and provide real-time tracking information. Express shipping options are available for urgent requirements.