Opening a stone processing factory is a large-scale project that involves multiple areas of preparation. Although the stone industry has enormous market potential, thorough planning and preparation are required before entering the industry. Here are the key steps to consider when starting a stone processing factory:

1. Market Research and Demand Analysis

Before opening a stone processing factory, comprehensive market research is needed. Understanding the target market’s demand, competition, market size, and industry trends is the first step to success.

- Market Positioning: Analyze the demand for stone in areas such as construction, interior design, tombstones, and artistic carvings.

- Competition Analysis: Study existing stone processing factories, understand their product quality, pricing, and services, and identify gaps in the market and competitive advantages.

- Customer Group Analysis: Identify potential clients such as construction companies, renovation firms, and design companies, and understand their needs for stone products.

2. Factory Location and Equipment Procurement

Choosing the right location for your factory is crucial. The geographical location directly impacts production efficiency and transportation costs.

- Location: Choose a location near stone material sources or with convenient transportation to help reduce raw material transportation costs.

- Factory Size and Layout: Select an appropriate factory size based on expected production volume and design a layout that ensures smooth production lines and minimizes material handling waste.

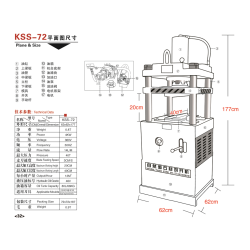

- Equipment Procurement: Choose suitable stone processing machinery such as cutting machines, polishing machines, engraving machines, grinding machines, etc. Consider production needs, equipment performance, and supplier support when purchasing.

3. Stone Processing Equipment

The success of a stone processing factory largely depends on the equipment chosen. Below are some common stone processing machines and their applications in production:

- Bridge-Type Stone Cutting Machines: One of the most essential pieces of equipment in a stone processing factory, primarily used for cutting stone blocks. These machines offer precise cutting of various types of stone, ensuring smooth and flat cutting surfaces.

- CNC Stone Cutting Machines: These machines use CNC technology to precisely control the cutting process, capable of cutting complex patterns and shapes, making them ideal for high-precision stone processing.

- Polishing and Buffing Machines: Polishing machines are used for coarse grinding of stone surfaces, while buffing machines are used for fine polishing, ensuring the surface is smooth and shiny, enhancing the stone’s aesthetic value.

- Engraving Machines: Stone engraving machines are used for intricate carving work, making decorative patterns, engraving text, and creating art pieces. They are widely used in the stone decoration sector.

- Cutting Saws: These machines are used for cutting thinner or softer stones, suitable for cutting stones of various sizes and shapes, improving production efficiency.

- Grinding Machines: Used for fine grinding and polishing stone surfaces, ensuring flatness and surface quality, especially important in marble and granite processing.

- Cutting Tables and Processing Lines: To improve production efficiency, automated production lines and cutting tables can be set up for efficient mass processing.

- When purchasing equipment, ensure you choose suppliers with reliable after-sales service and technical support to minimize downtime and maintenance costs.

4. Company Registration and Obtaining Relevant Licenses

Opening a legal stone processing factory requires completing a series of legal formalities and obtaining necessary qualifications.

- Company Registration: Register a company in accordance with local laws and obtain a business license.

- Industry Qualifications: Apply for relevant industry licenses to ensure the factory meets environmental protection and safety production requirements.

- Environmental Approval: Since stone processing generates a lot of dust and wastewater, the factory must comply with environmental regulations and obtain necessary environmental approvals.

5. Hiring Employees and Training

Employees are the core resource of the stone processing factory. Hiring skilled workers and providing training is essential.

- Worker Recruitment: Hire skilled workers, such as cutting operators, polishing operators, engraving workers, etc.

- Management Personnel: Hire experienced management staff, including factory managers, production supervisors, and quality control personnel.

- Employee Training: Provide training on machinery operation, production processes, safety, and environmental protection to enhance employee skills and efficiency.

6. Raw Material Procurement and Supply Chain Management

A stable raw material supply channel is critical to ensure that production runs smoothly.

- Raw Material Suppliers: Select reliable stone suppliers to ensure stable and high-quality raw materials.

- Raw Material Inventory Management: Set up an inventory management system to avoid production disruptions caused by a lack or excess of inventory.

7. Production Process and Quality Control

- Stone processing involves multiple stages, so standardizing production processes and implementing strict quality control are crucial.

- Production Process Design: Design a scientific and reasonable production process that ensures each step runs smoothly and reduces unnecessary losses.

- Quality Control System: Establish a quality management system to ensure every finished stone product meets client requirements in terms of cutting precision, surface smoothness, and engraving details.

8. Marketing and Customer Expansion

Once the stone processing factory is set up, how to promote the products and attract customers is key to success.

- Brand Building: Create a brand with market influence and promote it through online and offline channels.

- Sales Channels: Set up an online store and collaborate with construction companies and interior design firms to expand sales channels.

- Customer Relationship Maintenance: Set up a customer relationship management system to follow up with clients regularly, understand their needs, and continuously improve products and services.

9. Financial Management and Fundraising

Starting a stone processing factory requires a significant financial investment. Proper financial management and funding planning are essential.

- Fundraising: Determine funding sources through bank loans, investments, or other financing options.

- Cost Management: Control costs related to raw materials, equipment, labor, and other operational expenses to ensure profitability.

- Tax and Compliance Management: Ensure the company complies with tax regulations and pays taxes on time to avoid operational disruptions.

10. Safety Production and Environmental Protection Measures

The work environment in a stone processing factory requires attention to safety and environmental protection to prevent accidents.

- Safety Equipment: Equip the factory with necessary safety measures such as fire safety, first aid equipment, and personal protective equipment.

- Environmental Protection Facilities: Install wastewater treatment systems, dust removal equipment, and other environmental protection devices to ensure compliance with environmental regulations.

11. Continuous Improvement and Innovation

Stone processing factories need to continuously pursue technological innovation and management optimization to maintain competitiveness.

- Equipment Upgrades: Regularly assess equipment production efficiency and technology level and make necessary upgrades.

- Process Innovation: Explore new processing techniques to improve production efficiency and reduce costs, all while maintaining product quality.

Conclusion

Opening a stone processing factory is a complex process that requires careful planning and execution. By conducting thorough market research, securing funding, selecting appropriate equipment, and training employees, you can ensure smooth factory operation and establish a strong position in a competitive market. We hope this article provides useful guidance for your entrepreneurial journey.

Leave a Comment