Waterjet vs. Bridge/CNC Stone Cutting: Which Fits Your Factory in 2025?

Planning a new cutting line or upgrading in 2025? This guide compares waterjet with bridge saws and 5-axis CNC stone cutting machines so you can match technology to your materials, order mix, and ROI goals. It is written by the team at Shuinan Machinery (also written as shuinan machinery) based on thousands of global installations.

Executive Summary

- High customization, thin porcelain/sintered stone, mosaics, logos → Waterjet shines for edge integrity and inner corners.

- High-throughput straight cuts on granite/marble/quartz slabs → Bridge saw or 5-axis CNC delivers speed and lower cost per meter.

- Mixed orders → A hybrid line (Bridge/CNC for primary cuts + Waterjet for complex shapes) often yields the best payback.

Cut Quality & Chipping Control

Waterjet produces very fine kerfs and virtually no heat-affected zone, which helps avoid micro-chipping on porcelain/sintered stone. For granite/marble, modern bridge/5-axis CNC saws with the right blade, feed, and coolant achieve excellent edges; minor arrises are typically removed with a quick polish.

Speed & Throughput

- Bridge/CNC: Faster linear cuts, miters, and sink cutouts in a single setup; ideal for large rectangular yield patterns.

- Waterjet: Slower for long straight lines but more efficient for intricate geometries where saws require multiple passes.

Complex Shapes & Programming

Waterjet excels at tight inner corners, filigree, logos, and delicate inlays. 5-axis CNC handles curves, miters, sink holes, and bevels in one clamp, and with templates/macros can be very productive for countertop shops.

Operating Cost (TCO) Comparison

Evaluate technology using cost per linear meter (or part):

Cost per meter = (Energy + Consumables + Labor + Maintenance + Depreciation) / Meters cut

- Waterjet: Adds high-pressure pump power, abrasive media, water treatment, and intensifier maintenance.

- Bridge/CNC: Diamond blade cost is lower per meter; focus is on blade selection, dressing, and spindle health.

Materials Matrix: What Fits Where?

| Material / Use Case | Waterjet | Bridge Saw | 5-Axis CNC |

|---|---|---|---|

| Granite (20–30 mm), large runs | ● Good for complex inlays | ◎ Best for fast straight/mitre cuts | ◎ Excellent for one-stop sink + mitre |

| Marble (20 mm), delicate edges | ◎ Excellent edge protection | ● Good with correct blade/coolant | ◎ Excellent with fine passes |

| Porcelain / Sintered Stone (6–12 mm) | ◎ Best minimal chipping | ● Good; control feed/angle/coolant | ◎ Excellent with optimized toolpaths |

| Mosaics, logos, tight inner corners | ◎ Best | ○ Possible with multiple passes | ◎ Very good; more programming |

| Thick blocks / quarry work | ● Good with wirejet options | ◎ Excellent with block saws | ● Good for profiling |

Environment, Safety & Compliance

- Waterjet: Requires water recycling/filtration and abrasive disposal management; low airborne dust.

- Bridge/CNC: Wet cutting plus mist collection helps meet dust limits; plan for sludge handling and coolant recirculation.

Footprint & Utilities

- Waterjet: Needs space for high-pressure pump, abrasive supply and recovery system, and water treatment.

- Bridge/5-Axis: Compact footprint relative to throughput; consider slab loading, vacuum tables, and conveyors.

How to Decide for 2025: A Simple Checklist

- Order mix: If complex shapes > 25% or porcelain share is high, include a waterjet.

- Throughput target: For high daily meters of straight cuts, prioritize Bridge/5-Axis.

- Budget & payback: Model TCO with your local energy and labor rates.

- Operator skill: Waterjet emphasizes pump/abrasive maintenance; 5-axis emphasizes CAD/CAM toolpaths.

- Shop constraints: Check power, water, drainage, and crane/loader conditions.

Typical Line Configurations

- Speed Line: Bridge saw (primary) → Edge polish → QC. Lowest cost per meter for countertops and tiles.

- Precision Line: 5-axis CNC single-clamp operations for miters, sink cutouts, drainboards.

- Hybrid Line: Bridge/CNC for primary cuts + Waterjet cell for porcelain/mosaics/logos to minimize rework.

Why Work with Shuinan Machinery

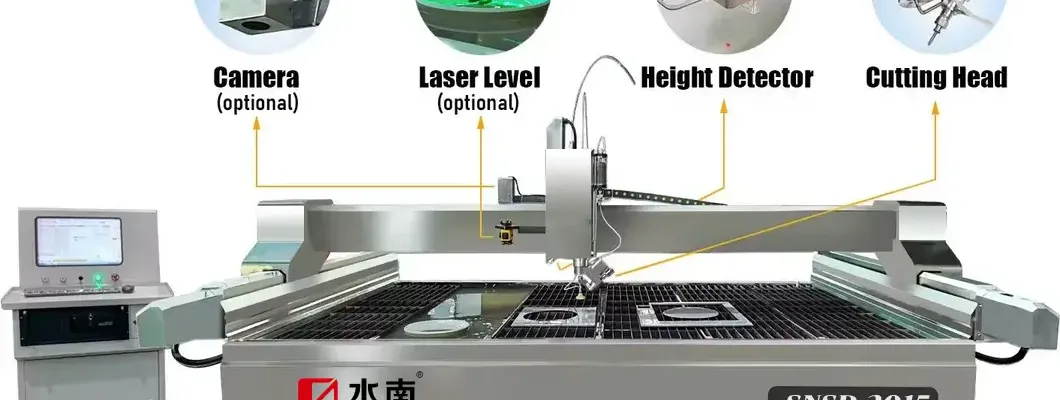

- Full portfolio: bridge saws, 5-axis CNC stone cutting, porcelain solutions, polishing lines.

- Application engineering: we tune blades, feeds, and coolant to your materials and yield plan.

- Global commissioning, operator training, and fast spare-parts support.

Talk to an Engineer

Share your slab specs and daily targets—our team will return a tailored ROI sheet and line layout.

WhatsApp (click to chat): +86 19805955837

FAQ

Q1: Does waterjet always replace a bridge saw?

A: No. Waterjet is unbeatable for intricate shapes and porcelain, but bridge/CNC remains faster and cheaper for straight cuts and thick granite.

Q2: How long is the learning curve for a 5-axis CNC?

A: With templates and training, many shops run production in 1–2 weeks; advanced toolpaths follow as operators gain confidence.

Q3: Can I start with a bridge saw and add waterjet later?

A: Yes. Many factories begin with a bridge/5-axis and add a waterjet cell when porcelain/complex jobs increase.

About Shuinan Machinery: A global stone machinery manufacturer providing bridge saws, 5-axis CNC cutting machines, polishing lines, and turnkey factory solutions. Contact us to design the right 2025 cutting strategy for your plant.

Leave a Comment