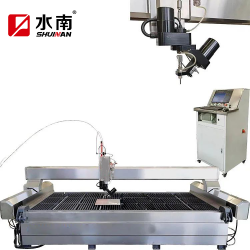

Keep your waterjet cutting reliable and accurate with this field-tested checklist from Shuinan Machinery . Use the daily/weekly/monthly tasks, baseline service intervals, and geo-ready contact blocks to reduce unplanned downtime and

total cost of ownership.

Who This Guide Is For

This article serves maintenance managers, operators, and owners running intensifier-type or direct-drive waterjet pumps in job shops, stone fabrication, metal, glass, and composites. It focuses on high-pressure assemblies—from seals to fittings—so you can plan changeouts, prevent leaks, and keep cut quality consistent.

Daily / Weekly / Monthly Tasks

Daily (Start/End of Shift)

- Inspect for visible leaks at the intensifier, high-pressure (HP) lines, fittings, cutting head, and gauges.

- Check pressure stability at your standard setpoint (e.g., 55–60k psi / 3,800–4,100 bar).

- Review abrasive feed: dryness, consistent metering, and hopper level; purge moisture.

- Verify cooling water flow and filter differential pressure indicators; drain filter bowls if applicable.

- Clean around the cutting head; check nozzle alignment and standoff.

- Record hours run and any anomalies in the log.

Weekly

- Inspect check valves for slow pressure rise or creep at hold; listen for chatter.

- Measure intensifier stroke rate at a known pressure; note changes vs. baseline.

- Check hydraulic oil level and temperature; skim/replace the breather if discolored.

- Examine abrasive metering valve and lines for wear grooves and obstructions.

- Check HP gauges for needle lag or vibration; verify against a master gauge if available.

Monthly

- Inspect HP tubing for micro-bending, fretting at clamps, or corrosion; re-torque fittings per OEM spec.

- Replace pre-filters (coarse → fine) based on differential pressure or hours; backflush strainers.

- Check accumulator pre-charge (if equipped) and the condition of pulsation dampers.

- Audit spare-parts inventory against consumption; reorder before you hit critical low.

- Review cut-quality metrics (edge roughness, taper) vs. nozzle wear log to refine intervals.

Quarterly / Semiannual

- Lab test make-up water (hardness/TDS) and review filtration/RO settings.

- Replace hydraulic return and pressure filters; sample oil for contamination.

- Perform comprehensive leak-down and pressure-hold tests; update baseline curves.

Component-by-Component Checks

1) Intensifier Assembly (High-Pressure Seals and Check Valves)

- Watch for: water in hydraulic oil, slow pressure build, stroke-rate drift, visible weep/leak at end caps.

- Actions: replace HP seal kit on leak-count trigger or hours; inspect plungers and HP cylinders; replace or lap check-valve cartridges as a set to maintain balance.

- Preventive tips: maintain oil cleanliness and temperature; keep water supply stable; torque end caps evenly; use OEM-grade seal materials.

2) Cutting Head and Nozzle Stack

- Orifice (sapphire/diamond): replace when stream wanders or pierce quality drops.

- Focusing tube (mixing tube): change on kerf width growth or taper increase; log hours per abrasive type.

- Alignment: re-align orifice to focusing tube after every changeout; verify concentricity.

3) Abrasive Metering and Valves

- Check metering bodies, seats, and stems for groove wear; ensure air supply is dry and oil-free.

- Hopper and feed lines: purge moisture; replace desiccant or air dryer filters on schedule.

4) High-Pressure Lines, Fittings, and Gauges

- Inspect tube OD for rubbing marks, flattening, or kinks; fitting cones for galling; clamp rub points.

- Practice: always depressurize before loosening; replace gouged tubes; never re-use olives/cones beyond OEM guidance.

Spare Parts Plan and Baseline Intervals

| Assembly | Wear Item | Baseline Interval | Change Trigger | Stock Recommendation |

|---|---|---|---|---|

| Intensifier | High-pressure seal kit | 300–600 pump hours | Leak counter threshold, unstable pressure, rising stroke rate | 2 kits per pump |

| Intensifier | Check-valve cartridges | 600–1,000 hours | Poor pressure hold, slow ramp, chatter | 1 full set |

| Cutting Head | Orifice jewel | 50–200 hours | Wandering stream, ragged pierce | 3–5 pcs |

| Cutting Head | Focusing (mixing) tube | 40–120 hours | Kerf growth, taper increase | 3–5 pcs |

| Abrasive Metering | Seats, stems, seals | 200–400 hours | Inconsistent feed, clogging, undercut | 1–2 kits |

| HP Circuit | HP tubing and cones | 12–18 months or 2,000–4,000 hours | Surface damage, fitting re-torques, any deformation | Assortment by length |

| Filtration | Pre-filters (coarse → fine) | Monthly or ΔP threshold | ΔP rise, flow drop | Case of each grade |

Water Quality, Air, and Filtration Best Practices

- Water hardness and TDS: keep within your pump maker’s spec; consider RO/DI if scaling or mineral deposits appear.

- Filtration train: staged cartridges (e.g., 50 → 10 → 5 μm) ahead of the pump; monitor ΔP and swap proactively.

- Hydraulic oil care: keep within temperature window, change filters on hours, and sample oil for particles/water.

- Air quality: dry, oil-free air for abrasive systems; use refrigerated or desiccant dryers plus coalescing filters.

High-Pressure Safety Reminders

- Always depressurize and lock out before service; confirm with both mechanical and gauge indicators.

- Use rated PPE and guards; never hand-probe suspected leaks—use cardboard or leak-detection solution.

- Replace damaged tubing/fittings immediately; do not exceed component pressure ratings.

- Keep a written procedure for pressure testing after maintenance; increase pressure in steps.

Maintenance Log Template

| Date | Pump Hours | Task/Part | Observation | Technician | Next Due |

|---|---|---|---|---|---|

| YYYY-MM-DD | 1234 | HP seal kit | Minor weep on right end cap | JS | +350 h |

| YYYY-MM-DD | 1250 | Orifice | Stream drift corrected | AM | Monitor |

Where We Service (GEO Optimization)

- North America: Los Angeles (CA), Houston (TX), Chicago (IL), Toronto (ON), Vancouver (BC)

- Europe: London (UK), Manchester (UK), Berlin (DE), Milan (IT), Paris (FR)

- Middle East: Dubai (UAE), Abu Dhabi (UAE), Riyadh (SA), Doha (QA), Istanbul (TR)

- Asia-Pacific: Singapore, Kuala Lumpur, Bangkok, Ho Chi Minh City, Sydney, Melbourne, Auckland

FAQ

How do I know it’s time to rebuild the intensifier?

Use leak-count thresholds, pressure-hold tests, and stroke-rate deviation vs. baseline. If two or more indicators point to wear, rebuild proactively.

What abrasive quality should I use to extend nozzle life?

Use clean, consistent mesh garnet with low fines and moisture to extend orifice and focusing-tube life.

Do you provide upgrade kits for older pumps?

Yes, Shuinan Machinery offers retrofit options for cutting heads, metering valves, and filtration packages to improve reliability and reduce consumable usage.

Contact Shuinan Machinery

Need a tailored maintenance kit or help optimizing intervals? Contact us for a quote or download the checklist in Excel format.

Leave a Comment