From Quarry to Finish: A Step-by-Step Guide to Stone Processing

Introduction to Stone Processing

Stone processing is a highly intricate process, involving several key steps to transform raw stones from quarries into beautifully finished products suitable for construction, architecture, and décor. At Shuinan Machinery, we offer state-of-the-art machinery that ensures efficiency and precision at every stage of stone processing. This guide will walk you through the entire process, from quarrying to the final polished stone.

Step 1: Quarrying the Stone

The first step in stone processing is quarrying the raw material. Large stones are extracted from quarries, often using specialized machines like diamond wire saws or hydraulic cutters. These tools make the extraction process more efficient, helping to remove large blocks of stone with minimal waste.

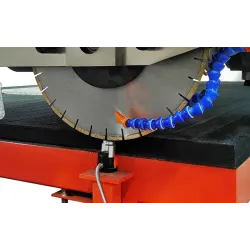

Step 2: Primary Cutting and Shaping

Once the stone has been extracted, it undergoes primary cutting and shaping. This is where machines such as stone cutting saws and block splitters come into play. They cut the large blocks into smaller, more manageable slabs, which can then be further processed. Precision cutting is crucial at this stage to ensure the final product meets the required specifications.

Step 3: Surface Treatment

After primary cutting, the stone undergoes surface treatments. Depending on the desired finish, this could include polishing, honing, or sandblasting. Stone polishing machines are used to achieve a smooth, shiny surface, perfect for countertops or flooring. At Shuinan Machinery, we offer advanced polishing equipment that guarantees a flawless finish.

Step 4: Quality Control and Inspection

Quality control is an essential part of the stone processing process. After treatment, each stone piece is inspected for any defects, color inconsistencies, or cracks. We use advanced technologies to detect imperfections and ensure that only the highest-quality stones make it to the final stages.

Step 5: Packaging and Shipping

Once the stone has passed quality control, it is carefully packaged and prepared for shipment. Protective packaging is used to ensure the stones are not damaged during transportation. At Shuinan Machinery, we offer customized packaging solutions based on the type of stone and the destination, ensuring safe delivery to our clients worldwide.

Leave a Comment