Stone Mining Quarry Methods: Principles, Choices, and Environmental Considerations

Modern stone quarrying has evolved far beyond traditional manual splitting and blasting. With continual technology upgrades—and rising attention to environmental performance—operators now have multiple mining options to balance output, cost, and sustainability.

Three Fundamentals Before You Choose

- Technical suitability: Is the method feasible for your geology, bench layout, and production targets?

- Cost control: Do equipment, labor, consumables, and energy align with your budget and payback goals?

- Environmental stewardship: How will you minimize dust, noise, waste rock, water use, and landscape impact?

Common commercial stones include marble and granite. For marble, open-pit, step (bench) mining is standard. Today, three open-pit approaches dominate:

- Diamond wire saw quarrying

- Circular (disc) saw quarrying

- Static cracking agent (expansive mortar) quarrying

1) Diamond Wire Saw Quarrying

Working principle: A dedicated cutting unit drives a diamond-impregnated wire along a predetermined kerf. High-pressure hydraulics provide steady traction, while the operator controls motion remotely for safety. Continuous grinding separates the block cleanly with very low vibration and noise, preserving the rock’s structural integrity.

Cooling & dust control: A synchronized water system maintains optimal wire temperature and continuously flushes fines, reducing airborne dust and environmental load.

Key advantages:

- Geometry freedom: Horizontal, vertical, or diagonal cuts—even complex block recovery.

- Quality & speed: Fast cutting, straight kerfs, minimal micro-cracking; often no secondary trimming required.

- Remote operation: Safer cutting in challenging zones (underwater sections, unstable faces, restricted areas).

Typical applications: Versatile across marble, granite, and engineered stones; ideal where block quality and recovery rate are top priorities.

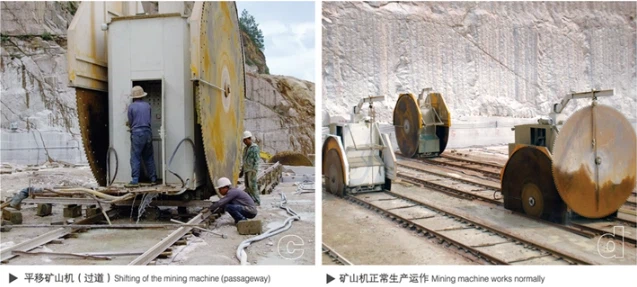

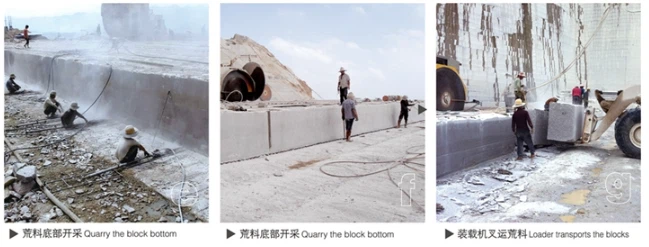

2) Circular (Disc) Saw Quarrying

Concept: A large-diameter, track-mounted disc saw—such as double-blade quarrying systems from Shuinan Machinery—drives super-sized blades with high-efficiency permanent-magnet motors. The machine traverses on a rail to produce orthogonal (cross) cuts, vertically segmenting the ore body into blocks.

Why operators choose it:

- Non-blasting, non-thermal cutting reduces shock damage and improves block integrity.

- High stability & throughput in well-structured, medium-to-large quarries with predictable benches.

- Lower waste and cleaner faces compared with legacy methods, supporting better yield and easier downstream processing.

Notes on deployment: Best suited to quarries with stable production plans and adequate bench access. Shuinan Machinery provides matched auxiliaries (dust suppression, water circulation, handling systems) to complete the process chain.

3) Static Cracking Agent (Expansive Mortar) Quarrying

How it works: Operators drill a line of holes (commonly ~20 cm spacing), then pour a powdered expansive agent (primarily special calcium-oxide formulations with additives) mixed with water into each hole. As it hydrates overnight, expansive crystals generate high pressure, opening the stone along the drilled line.

Pros & cons:

- Pros: Safer than explosives; applicable in sensitive zones where blasting is prohibited.

- Cons: Slow reaction time (often 10+ hours), significant dust and noise during drilling, and unpredictable fracture lines that can reduce block quality.

Current practice: Because of low efficiency, inconsistent splitting, and environmental concerns, most new quarries rarely adopt this method as a primary approach.

Method Selection Guide

- Target block size & quality: Wire and large disc saws deliver straight, clean cuts with minimal micro-cracking, maximizing commercial grade and yield.

- Geology & bench condition: Highly variable or fractured deposits often favor the flexibility of diamond wire; uniform benches benefit from disc saw productivity.

- Cost & utilization: Evaluate kW demand, consumable wear (wire, segments), crew skill, and cycle time per block.

- ESG requirements: Prioritize dust suppression, water recycling, and low-noise operation. Both wire and disc routes pair well with closed-loop water systems and modern dust capture.

Environmental & Safety Considerations

- Dust & slurry: Use wet cutting and closed-loop water recycling (settling, filtration, de-sludging) to minimize discharge.

- Noise & vibration: Wire and disc saws produce lower vibration than blasting; enclosures and scheduling reduce community impact.

- Resource efficiency: Cleaner kerfs and precise block extraction lower waste rock and reduce downstream energy per usable cubic meter.

- Operator safety: Remote controls (wire saws) and safeguarded work zones (disc saws) reduce exposure to hazards.

Why Many Sites Choose Shuinan Machinery

Shuinan Machinery delivers complete quarry cutting solutions—from diamond wire saw systems to double-blade circular quarry saws—engineered for high recovery, stable cuts, and lower lifetime cost. Our packages include:

- High-efficiency drive systems and matched hydraulics

- Integrated dust suppression and water recycling options

- Application engineering for bench design, cut sequencing, and yield optimization

- Global training, commissioning, and lifecycle support

Summary

- Diamond wire saw: Maximum flexibility and cut quality; low vibration/noise; excellent for complex geometries and sensitive zones.

- Circular (disc) saw: High productivity and clean orthogonal cuts in stable, large-scale benches; no blasting required.

- Static cracking agent: Niche solution; slower, less predictable, and generally not preferred for new operations.

For quarry owners balancing quality, cost, and ESG, modern wire and disc systems from Shuinan Machinery provide a reliable path to higher yield and cleaner operations.

Leave a Comment