Shuinan Machinery: China's Top Stone Polishing Machine Manufacturer, Delivering Excellence in Cutting and Polishing

The stone processing industry demands precision equipment that can transform raw materials into stunning finished products with mirror-like surfaces and flawless edges. In this competitive landscape, establishing leadership as China's Top Stone Polishing Machine Manufacturer requires exceptional engineering capabilities, advanced technology integration, and unwavering commitment to quality excellence. ShuiNan Machinery has achieved this prestigious position through decades of innovation and manufacturing mastery that consistently delivers superior polishing solutions to global markets.

The Science and Art of Stone Polishing Technology

Understanding Polishing Machine Applications

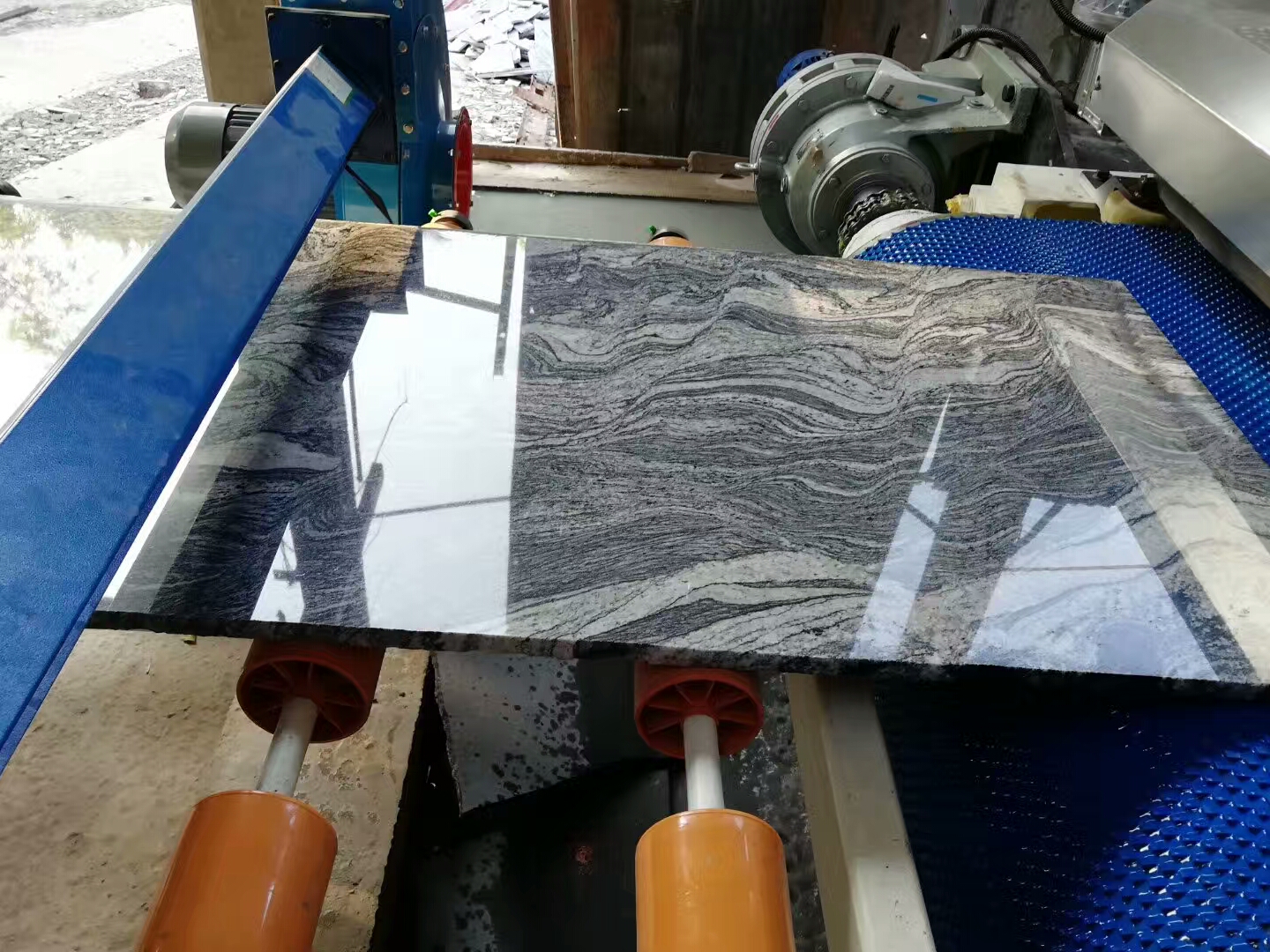

Stone polishing represents the critical final stage of stone processing, transforming rough-cut surfaces into sophisticated architectural elements and decorative features. Modern Stone Polishing Machine technology encompasses multiple operational approaches, from handheld units for detail work to massive automated systems capable of processing entire slabs with consistent precision.

Granite polishing applications require robust equipment capable of handling extreme hardness while achieving mirror-finish surfaces that highlight natural crystalline structures. The abrasive progression from coarse grinding compounds to fine polishing media demands precise pressure control and consistent motion patterns that only professional-grade equipment can maintain over extended operational periods.

Marble polishing presents entirely different technical challenges, as the material's softer composition requires gentle handling to prevent surface scratching while achieving the lustrous finish that defines quality marble installations. Temperature control becomes critical during polishing operations, as excessive heat generation can cause thermal stress and surface discoloration that compromises final appearance.

Engineered stone materials, including quartz composites and artificial surfaces, have created new polishing requirements that combine aspects of both natural stone processing and synthetic material handling. These applications demand versatile equipment capable of adapting to varying material compositions while maintaining consistent surface quality across production runs.

Technological Innovation in Polishing Systems

Advanced polishing systems integrate multiple operational components into cohesive platforms that optimize efficiency while maintaining surface quality standards. Variable speed control enables operators to match rotational velocities to specific material requirements and abrasive media characteristics, preventing surface damage while maximizing polishing effectiveness.

Water cooling and lubrication systems prevent thermal buildup that can cause surface discoloration and equipment wear, while simultaneously removing debris and controlling dust generation. Proper cooling system design ensures consistent temperature control across extended operational periods, maintaining surface quality regardless of processing volume.

Automated feed systems provide consistent pressure application and motion control that human operators cannot achieve manually, resulting in uniform surface finishes across large processed areas. These systems incorporate feedback mechanisms that adjust operational parameters based on real-time surface condition monitoring.

Given the technical complexity and precision requirements of modern stone polishing, manufacturers must demonstrate exceptional capabilities across engineering, production, and quality control to earn industry recognition. Few companies have successfully mastered all these demanding aspects simultaneously, making true market leadership a rare achievement in this specialized field.

ShuiNan Machinery's Polishing Excellence Leadership

Manufacturing Superiority and Market Position

ShuiNan Machinery's recognition as the premier Stone Polishing Machine supplier stems from systematic excellence across multiple operational dimensions that competitors struggle to match simultaneously. The company's 60,000 square meter facility incorporates specialized production lines dedicated exclusively to polishing equipment manufacturing, ensuring focused expertise and quality consistency.

Advanced manufacturing capabilities enable ShuiNan to produce polishing systems with precision-machined components that maintain operational tolerances essential for consistent surface quality. CNC machining centers fabricate critical components to exacting specifications, while specialized assembly procedures ensure proper alignment and calibration before equipment shipment.

Quality control processes throughout production cycles verify performance specifications and operational reliability that define the best Stone Polishing Machine standards in the industry. ISO9001:2015 certification validates systematic quality management procedures, while CE and TUV certifications demonstrate compliance with international safety and performance standards.

Annual production capacity exceeding 3,000 units enables competitive pricing through manufacturing economies while maintaining customization capabilities for specialized applications. This scale advantage, combined with 27 years of operational experience, positions ShuiNan Machinery at the forefront of polishing technology development and market leadership.

Comprehensive Polishing Solutions Portfolio

ShuiNan's polishing equipment portfolio addresses diverse application requirements across multiple market segments and operational scales. Bridge polishing systems provide precision surface finishing for large slabs and architectural elements, incorporating advanced pressure control systems and automated progression through multiple abrasive grades.

Edge polishing machines deliver consistent beveling and surface finishing for countertops, architectural trim, and decorative elements requiring precise dimensional control and uniform surface quality. These specialized systems incorporate guidance mechanisms that ensure consistent edge profiles while maintaining surface finish standards.

Handheld polishing units enable detailed work and restoration applications where larger equipment cannot access complex geometries or confined spaces. Despite their portable design, these units incorporate professional-grade motor systems and vibration dampening features that deliver results comparable to larger stationary equipment.

Multi-station polishing lines integrate multiple operational stages into automated production systems capable of processing materials from rough-cut condition to final polished finish without manual intervention. These comprehensive systems maximize productivity while ensuring consistent quality across high-volume production requirements.

Global Market Success and Customer Validation

International market penetration across more than 30 countries provides objective validation of ShuiNan's polishing equipment performance in diverse operational environments and regulatory frameworks. This geographic diversity demonstrates adaptability to different material types, quality standards, and operational requirements that vary significantly across global markets.

European customers consistently highlight ShuiNan's energy-efficient polishing technologies and environmental compliance features as key selection factors. Water recycling systems and dust control technologies address strict European environmental regulations while reducing operational costs, making ShuiNan equipment particularly attractive in environmentally conscious markets.

Southeast Asian markets have embraced ShuiNan polishing solutions as enabling technologies for achieving international quality standards in emerging stone processing industries. Comprehensive training programs and technical support ensure successful technology transfer and operational optimization in markets where local technical expertise may be limited initially.

Middle Eastern architectural projects have validated equipment performance under extreme environmental conditions while meeting demanding aesthetic standards for luxury construction projects. These successful installations serve as reference examples for other customers evaluating polishing equipment for similar demanding applications.

Application Excellence Across Industry Segments

Architectural and Construction Applications

Modern architectural applications demand polishing solutions capable of achieving mirror-finish surfaces on large-format slabs while maintaining dimensional accuracy across extended surface areas. ShuiNan's automated polishing systems deliver consistent results that meet stringent architectural specifications for commercial and residential installations.

Countertop fabrication represents a high-volume application where consistent edge polishing and surface finishing directly impact customer satisfaction and business profitability. ShuiNan's specialized countertop polishing equipment optimizes workflow efficiency while ensuring uniform quality across diverse material types and edge profiles.

Monument and memorial applications require exceptional surface quality and precision edge work that withstand outdoor environmental exposure while maintaining appearance over extended periods. ShuiNan's polishing solutions deliver the durability and aesthetic quality essential for these permanent installations.

Industrial and Manufacturing Integration

Large-scale stone processing operations require polishing solutions that integrate seamlessly with existing production workflows while maintaining consistent quality across high-volume processing requirements. ShuiNan's automated polishing lines provide the reliability and productivity essential for industrial applications.

Quality control integration enables real-time monitoring and adjustment of polishing parameters to ensure consistent results regardless of material variations or operational conditions. Advanced control systems automatically adjust operational parameters based on surface condition feedback and predetermined quality standards.

Maintenance accessibility and component standardization minimize operational downtime while reducing long-term ownership costs through efficient service procedures and readily available replacement components.

Innovation Leadership and Future Development

Advanced Technology Integration

ShuiNan Machinery's commitment to technological advancement ensures continued leadership in polishing equipment development and performance enhancement. Research and development initiatives focus on automation integration, surface quality improvement, and operational efficiency optimization that anticipate evolving market requirements.

IoT connectivity and remote monitoring capabilities enable predictive maintenance scheduling and operational optimization that minimize unplanned downtime while maximizing equipment utilization. These smart systems provide operators with real-time performance data and maintenance recommendations based on actual equipment condition.

Environmental sustainability initiatives have produced eco-friendly polishing solutions that minimize water consumption and eliminate harmful emissions while maintaining superior performance standards. These innovations position ShuiNan equipment as preferred solutions for customers focused on environmental responsibility and regulatory compliance.

ShuiNan Machinery's position as China's Top Stone Polishing Machine Manufacturer reflects systematic excellence in engineering innovation, manufacturing quality, and customer service that few competitors can match. Their comprehensive solutions portfolio, global market success, and commitment to technological advancement ensure continued leadership in the evolving stone polishing industry.

Discover ShuiNan Machinery's complete range of advanced polishing solutions and explore customization options for your specific processing requirements at https://shuinanmachinery.com/.

Leave a Comment