In the stone processing industry, production efficiency and cost control directly determine your business’s competitiveness. If your workshop is still using traditional manual grinding or inefficient equipment, you may have already missed out on key market opportunities. Today, we introduce a piece of equipment that can completely transform your production process—the Fully Automatic Continuous Grinder. Whether you're working with granite, marble, or any other stone, this machine will help you achieve more efficient and refined stone processing.

Common Pain Points in the Stone Processing Industry

In the face of intense market competition, traditional grinding equipment often causes significant challenges for stone processing enterprises. Here are some of the issues you may be facing:

Low production efficiency: Traditional stone grinding machines require a lot of manual labor, with slow production speeds that cannot meet large-scale production demands.

Inconsistent quality: Due to manual operation or equipment failures, the stone surface often has flaws, affecting the quality of the final product.

Frequent maintenance of equipment: Old stone grinders often break down, leading to production halts and extra costs for repairs.

High labor costs: Complex manual operations require extensive employee training, resulting in unnecessary costs.

If your business is facing these issues, it might be time to upgrade your equipment with a more efficient solution—the Fully Automatic Continuous Grinder.

Fully Automatic Continuous Grinder — An Efficient, Precise, and Reliable Solution for Stone Processing

The Fully Automatic Continuous Grinder is the ideal choice for modern stone processing businesses. With its automated control system, it significantly improves production efficiency while solving many of the challenges posed by traditional equipment.

1. Improve Production Efficiency

The Fully Automatic Continuous Grinder uses advanced automated control technology, allowing the machine to operate continuously without human intervention. Compared to traditional machines, it reduces production cycles and increases output. When it comes to large-scale production, you can significantly enhance the efficiency of your production line to meet the growing market demand for granite and marble products.

2. Exceptional Grinding Results

The Fully Automatic Continuous Grinder ensures that every piece of granite or marble reaches the highest quality standards thanks to its precise design. The finely engineered grinding heads ensure smooth, even surfaces, making it perfect for high-end construction and decoration projects. Whether you need to grind granite slabs or marble tiles, this machine ensures perfect results every time.

3. Save on Labor Costs

With its intelligent operation, the Fully Automatic Continuous Grinder minimizes manual intervention. The automated system not only saves on labor costs but also reduces the potential for human error that can lead to quality issues. Compared to traditional machines that require significant manual operation, this grinder offers a much more cost-effective solution for stone processing businesses.

4. Durability and Stability

Constructed with high-strength materials and superior craftsmanship, the Fully Automatic Continuous Grinder maintains excellent performance even under heavy, continuous use. The machine’s durability ensures a longer service life, reducing frequent maintenance costs and production downtime. It’s a reliable choice for those who want to invest in a stone grinding machine that will stand the test of time.

Advantages of the Fully Automatic Continuous Grinder Compared to Traditional Equipment

The Fully Automatic Continuous Grinder outperforms traditional machines in several areas, particularly in production efficiency, precision, and ease of operation. Here's how it compares:

Higher Automation: The automated system of the Fully Automatic Continuous Grinder requires minimal human intervention, ensuring stable production with less human error.

Precision and Consistency: With its precision control system, this stone grinder guarantees consistent results, ensuring high-quality outputs for mass production of granite and marble.

Reduced Maintenance Costs: The machine’s durable design and cutting-edge technology result in a lower failure rate, reducing maintenance costs and downtime.

Higher Production Efficiency: Compared to traditional equipment, the Fully Automatic Continuous Grinder works faster and produces more, making it a key asset for boosting your stone processing business.

Successful Customer Case

.jpg)

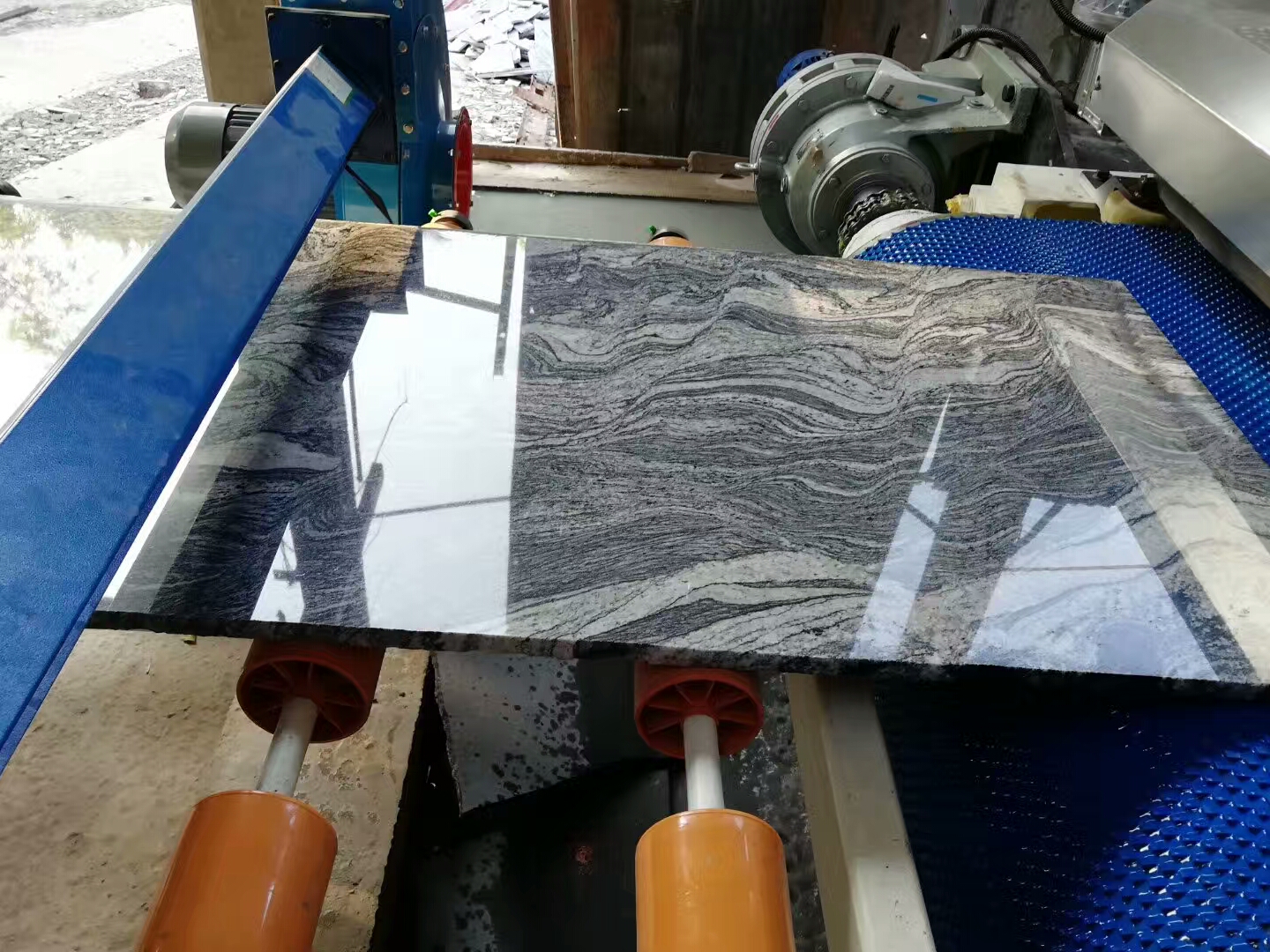

A large stone processing factory introduced the Fully Automatic Continuous Grinder and saw a 30% increase in production efficiency. The company’s manager commented: “Since we started using this machine, our production speed has greatly improved, and product quality has been consistently high. Most importantly, we’ve saved on labor costs, and the machine’s reliability has significantly reduced downtime.”

Take Action Now to Boost Your Stone Processing Productivity!

If you’d like to learn more about the Fully Automatic Continuous Grinder or schedule a free product demonstration, don’t hesitate to get in touch with us! Our expert team is ready to provide you with a tailored solution to enhance your production efficiency and product quality.

Choose the Fully Automatic Continuous Grinder and take your stone processing business to the next level!

Summary

In the stone processing industry, efficiency and quality are at the heart of competitiveness. The Fully Automatic Continuous Grinder not only boosts production efficiency but also ensures precise and consistent grinding results. As the demand for high-efficiency, high-precision equipment grows, upgrading your machinery will be a critical step in enhancing your business's competitiveness. If you're looking for a cost-effective, low-maintenance, and high-quality solution for stone processing, the Fully Automatic Continuous Grinder is the perfect choice.

Leave a Comment