How to Maintain Stone Machinery in Hot and Dusty Environments

Stone factories in hot and dusty regions such as the Middle East face unique challenges. High temperatures, fine dust, and long operating hours can significantly affect the performance and service life of stone processing machinery.

Without proper maintenance, machines may suffer from overheating, accelerated wear, reduced cutting accuracy, and frequent breakdowns. In this article, we share practical maintenance tips to help stone factories keep their machines running reliably in harsh working environments.

1. Control Dust to Protect Key Components

Stone dust is one of the biggest enemies of stone machinery. Dust can enter bearings, guide rails, motors, and electrical components, causing premature wear and failures.

Maintenance tips:

- Clean guide rails and moving parts daily

- Use protective covers for linear guides and ball screws

- Install dust extraction or water spray systems where possible

2. Lubrication Is More Important in Hot Climates

High temperatures can reduce lubricant effectiveness and accelerate oil degradation. Insufficient lubrication leads to increased friction and unstable machine operation.

Maintenance tips:

- Use lubricants suitable for high-temperature environments

- Shorten lubrication intervals during summer months

- Check lubrication points regularly for blockages caused by dust

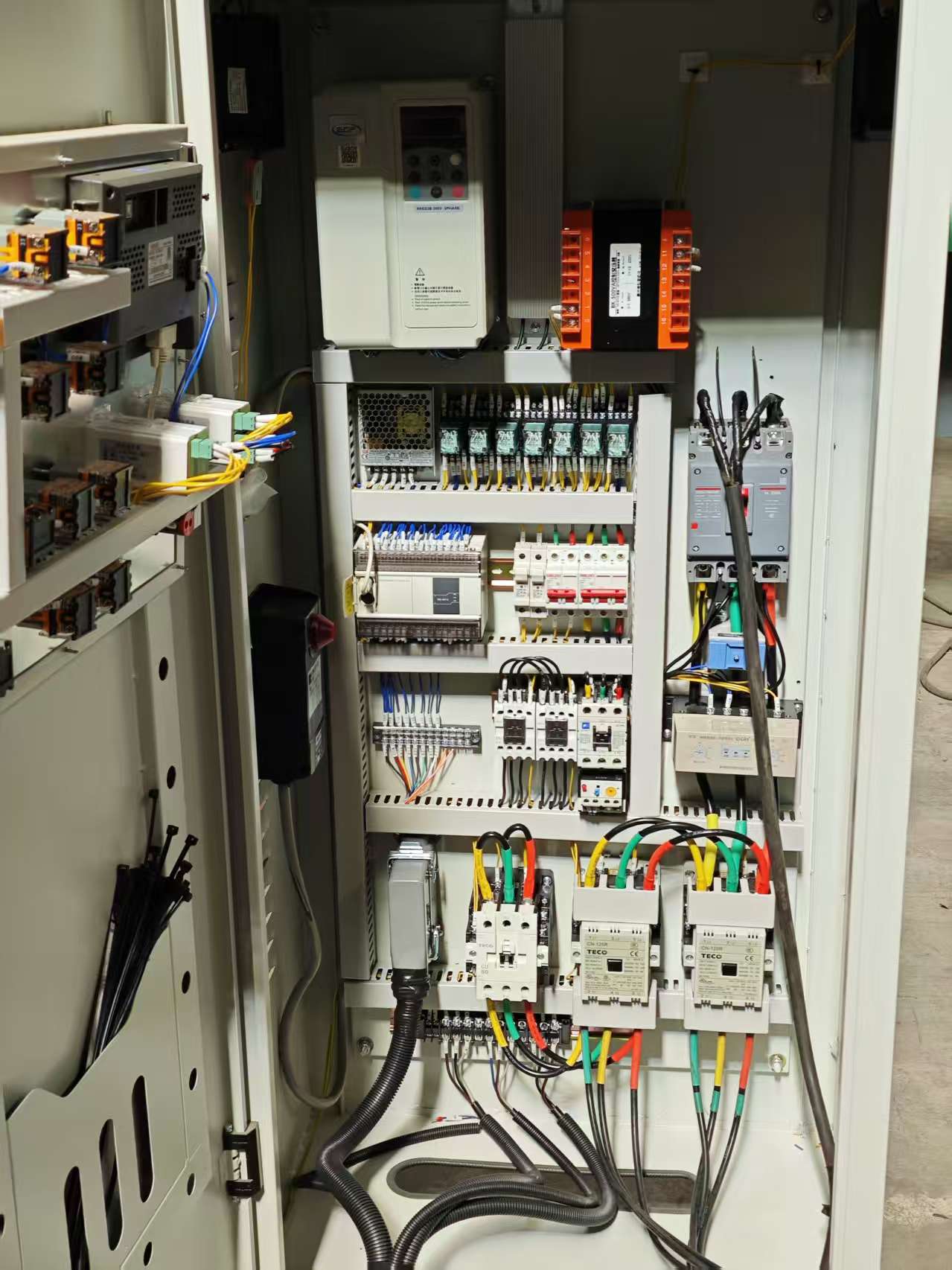

3. Monitor Electrical Systems Closely

Dust and heat combined can seriously affect electrical components, sensors, and control systems.

Maintenance tips:

- Inspect electrical cabinets weekly for dust accumulation

- Tighten electrical connections regularly

- Use sealed and industrial-grade electrical components

4. Maintain Cutting Tools and Blades

In hot environments, cutting blades can wear faster, especially when cutting hard stone such as granite.

Maintenance tips:

- Check blade condition and tension frequently

- Ensure sufficient cooling water during cutting

- Replace worn blades promptly to maintain cutting accuracy

5. Establish a Preventive Maintenance Schedule

Reactive maintenance leads to unexpected downtime and higher repair costs. Preventive maintenance is essential for stone factories operating in harsh conditions.

Recommended actions:

- Create daily, weekly, and monthly inspection checklists

- Record operating data and maintenance history

- Train operators to identify early warning signs

Why Machine Design Matters in Harsh Environments

Not all stone machines are designed to operate reliably in hot and dusty conditions. Machine structure, sealing design, cooling systems, and component quality all play a critical role.

Many Middle East stone factories prefer heavy-duty bridge saws and multi-blade bridge block cutting machines because of their stability, strong structure, and reliable long-term performance.

Conclusion

Maintaining stone machinery in hot and dusty environments requires more attention, but with the right practices, downtime can be significantly reduced and machine lifespan extended.

Regular cleaning, proper lubrication, effective cooling, and preventive maintenance are the keys to stable and efficient production in Middle East stone factories.

About Shuinan Machinery

Shuinan Machinery is a professional manufacturer of stone processing machinery, with extensive experience supplying equipment to stone factories in the Middle East, including Saudi Arabia.

Our machines are designed with heavy-duty structures, reliable cooling systems, and durable components to perform consistently in harsh working environments.

Contact Us

If you are looking for stone machinery suitable for hot and dusty environments or need professional maintenance advice, feel free to contact us.

WhatsApp: +86 198 0595 5837

Our team is ready to support your stone factory with reliable solutions.

Leave a Comment