The stone industry’s supply chain involves multiple stages, from quarry mining and transportation to processing and final product delivery. The efficiency of each stage directly affects overall costs and market competitiveness. Stone machinery plays a crucial role in optimizing these stages, improving production efficiency, and reducing costs. With modern machinery, businesses can significantly improve overall operational efficiency while maintaining quality.

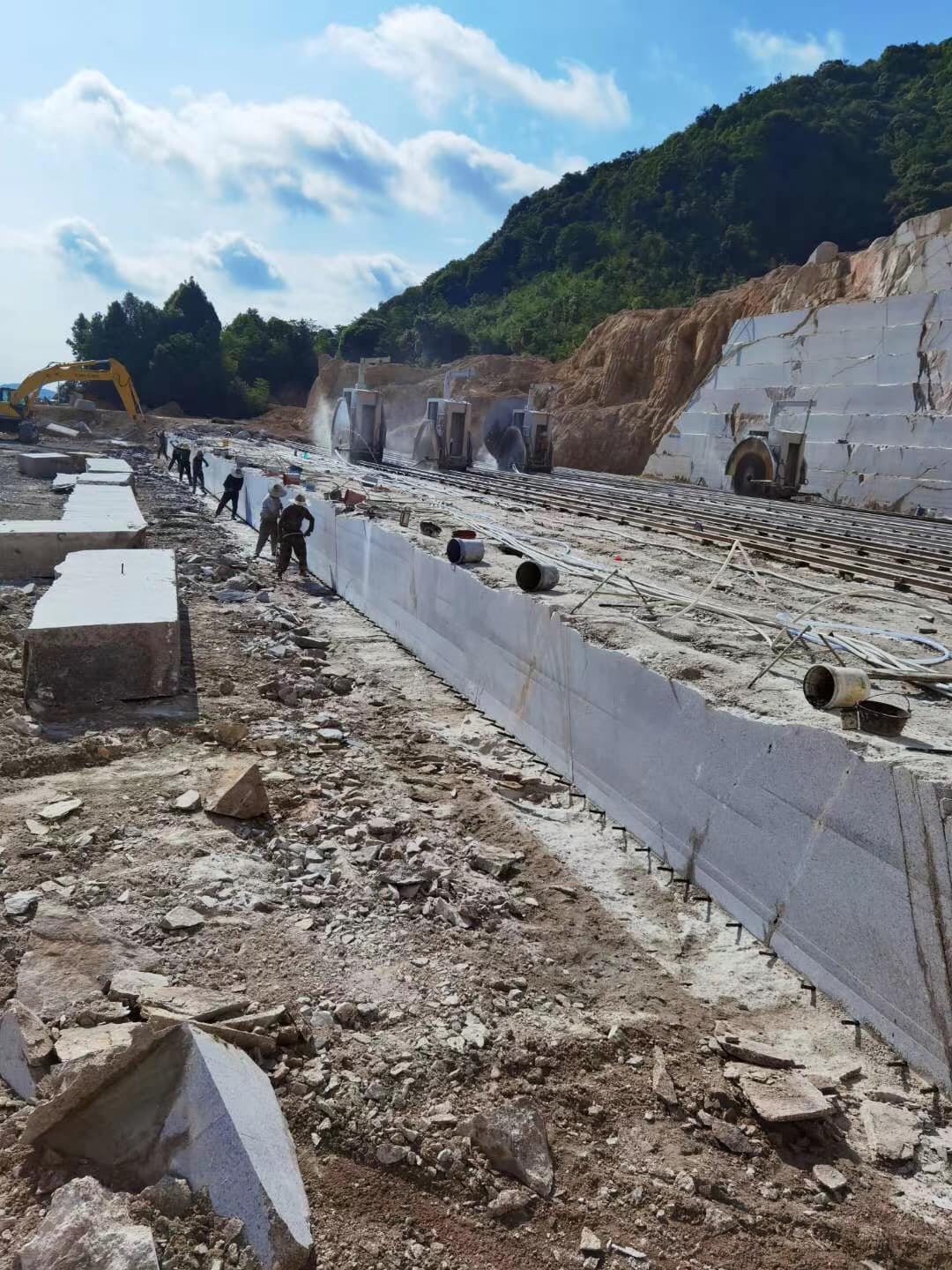

1. Quarry Mining: Enhancing Mining Efficiency and Resource Utilization

- Automated Mining Equipment: Smart mining equipment such as drills, excavators, and conveyors can automate operations, improving mining efficiency and resource utilization. By reducing human intervention and improving extraction precision, the mining process effectively minimizes material loss and reduces labor costs.

- Precise Mining Technologies: Modern mining equipment, such as laser scanning and 3D geological exploration technology, can precisely locate mineral resources, reducing waste and improving ore extraction rates. Precise mining helps maximize the commercial value of stone and lowers costs at the source.

2. Transportation: Reducing Logistics Costs

- Automated Transport Systems: Automated mining transport vehicles and conveyors can replace traditional manual handling, significantly improving transport efficiency and reducing the risk of material damage during transport. Smart logistics scheduling systems ensure timely and efficient delivery, reducing idle time and delays.

- Smart Scheduling and Route Optimization: Logistics systems based on big data and IoT technology can monitor transportation status in real time and optimize transport routes based on real-time data, further reducing fuel costs, labor costs, and delays.

3. Stone Processing: Precision Processing and High-Efficiency Production

- High-Efficiency Cutting and Precision Processing: Modern stone processing machinery such as CNC cutters and engraving machines enable precise cutting and processing, reducing material waste and increasing the value of each stone. These technologies also significantly improve processing speed, shortening production cycles.

- Automated Production Lines: Automated production lines reduce human intervention, optimize the processing flow, and improve production efficiency while ensuring consistent processing quality. Automation not only improves production precision but also reduces downtime and the occurrence of defective products, thereby lowering rework costs.

4. Factory Process Optimization: Improving Overall Efficiency

- Intelligent Production Scheduling: Intelligent production scheduling systems can monitor production conditions in real time and automatically adjust plans to avoid overproduction or underproduction. Precise scheduling maximizes equipment utilization, reducing production cycles and costs.

- Equipment Maintenance Management: Modern stone machinery is often equipped with advanced monitoring systems that track equipment status and predict potential issues in advance. Effective preventive maintenance reduces equipment failure and downtime, ensuring continuous and stable production.

5. Supply Chain Coordination and Information Technology: Enhancing Overall Supply Chain Efficiency

- Information Sharing and Collaborative Operations: Through information management systems such as ERP and MES, stone companies can achieve transparency and resource sharing between upstream and downstream, optimizing the coordination of production, procurement, and transportation. This ensures smooth supply chain operation.

- Optimized Inventory Management: Intelligent inventory management systems based on big data analysis can accurately forecast market demand, preventing overstocking or shortages of raw materials and finished products. Rational inventory management reduces capital occupation, lowers warehousing costs, and improves cash flow efficiency.

6. Energy Efficiency and Environmental Technologies: Reducing Resource Consumption and Improving Production Efficiency

- Energy-Efficient Equipment: More stone machinery is adopting energy-efficient designs, such as high-efficiency motors and heat recovery systems, to reduce energy consumption. Using energy-efficient equipment not only lowers production costs but also meets increasingly stringent environmental requirements.

- Waste Recycling and Reuse: Modern stone processing equipment is often equipped with waste recycling systems that can effectively collect and reuse waste materials generated during cutting and processing. This reduces waste, lowers costs, and contributes to environmental sustainability.

Conclusion: The Key Role of Stone Machinery in Supply Chain Cost Reduction and Efficiency Improvement

Stone machinery plays a vital role throughout the supply chain. By improving quarry mining efficiency, optimizing transportation, ensuring precise processing, and utilizing intelligent production management, stone companies can effectively lower overall costs, improve production efficiency, and enhance market competitiveness. With continuous technological advancements, stone machinery will become increasingly smarter and more energy-efficient, driving the ongoing innovation and development of the industry.

By selecting and continuously optimizing stone machinery, businesses can not only enhance their production capabilities but also stand out in the competitive market and achieve greater success.

Leave a Comment