Introduction:

In the global stone processing industry, the infrared bridge stone cutting machine has become the preferred choice for more and more stone processing enterprises due to its efficiency, precision, and strong adaptability. Especially in regions like Southeast Asia, Africa, and the Middle East, with the rapid development of the construction industry and infrastructure projects, the demand for high-quality stone processing equipment is steadily increasing. This article will introduce the working principles, advantages, and applications of the infrared stone cutting machine for customers in these regions, helping you choose the right equipment.

1. What is an Infrared Bridge Stone Cutting Machine?

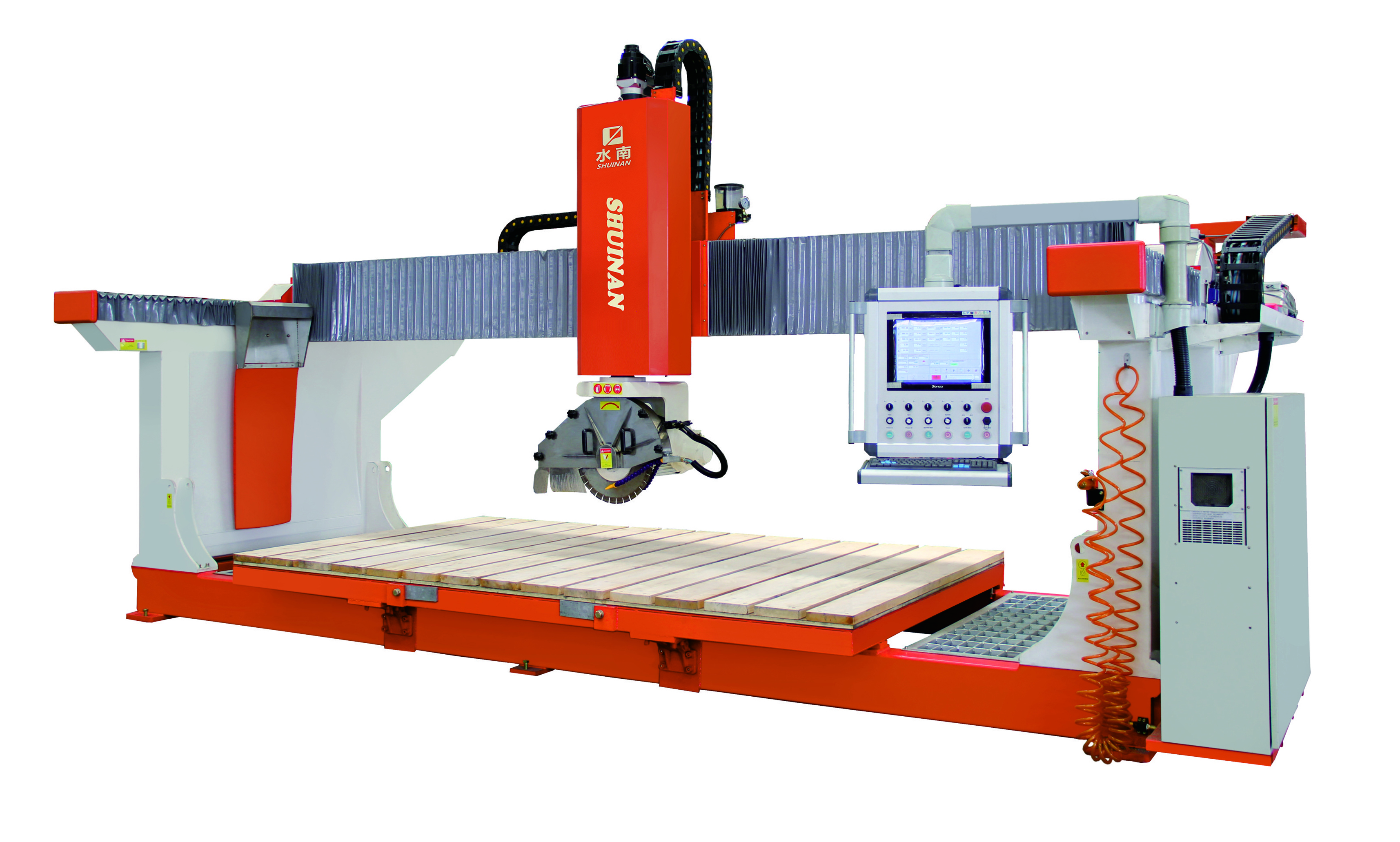

Definition and Working Principle: The infrared bridge stone cutting machine uses advanced infrared positioning technology to precisely control cutting position and depth, ensuring high precision in stone processing. The equipment consists of a cutting bridge, infrared positioning system, and electric cutting tools, capable of efficiently performing cutting and processing tasks for various types of stone.

Adaptability: The infrared stone cutting machine is especially suitable for various types of stone, including granite, marble, ceramics, etc., and is widely used in construction, carving, and decoration industries.

2. Advantages of Infrared Bridge Stone Cutting Machines

High Precision Cutting: The infrared technology provides real-time positioning and adjustment, ensuring the precision of each cut, especially for complex cutting tasks, meeting the needs of different customers.

Durability and Strong Adaptability: It is particularly suited for hot, humid, or arid environments. The infrared stone cutting machine is designed to withstand the climates of Southeast Asia and the Middle East, with strong corrosion resistance, ensuring long-term stable operation.

Improved Production Efficiency: The infrared bridge cutting machine is efficient and precise, reducing manual operation time and enhancing production efficiency, which significantly lowers operational costs, making it suitable for mass production and long-term use.

Energy-Efficient and Environmentally Friendly: Compared with traditional stone cutting machines, the infrared bridge cutting machine consumes less energy and offers higher energy utilization efficiency, helping to reduce energy costs while meeting green and sustainable production requirements.

3. Applications of Infrared Bridge Stone Cutting Machines in Southeast Asia, Africa, and the Middle East

Construction and Infrastructure: In these regions, stone cutting machines are widely used for processing materials for building facades, public square paving, floor tiles, and artistic carvings, meeting the demand for large-scale infrastructure construction.

Interior and Exterior Decoration: The infrared stone cutting machine also plays an important role in interior decoration, particularly in high-end buildings and luxury hotels, where precise cutting is required.

Customized Needs: Whether it’s the Middle East’s demand for intricate carvings or Southeast Asia’s need for diverse decorative materials, the infrared bridge stone cutting machine can efficiently complete customized stone cutting tasks to meet different market demands.

4. How to Choose the Right Infrared Bridge Stone Cutting Machine?

Consider Cutting Precision and Speed: Choose equipment with the appropriate cutting precision and processing speed according to project requirements. For complex patterns and fine cutting, select equipment with high precision and stability.

Adaptability to Climate Conditions: Southeast Asia, Africa, and the Middle East all have varying climates, so it is advisable to choose equipment that can withstand high temperatures, humidity, or arid conditions, ensuring stable operation over time.

Cost-Effectiveness: Considering the demands of local markets, select an infrared bridge cutting machine that offers excellent performance at a reasonable price to improve return on investment.

5. Conclusion

For customers in Southeast Asia, Africa, and the Middle East, the infrared bridge stone cutting machine is undoubtedly an ideal equipment for improving stone processing efficiency and ensuring cutting precision. Whether for large-scale construction projects or precise interior decoration cutting, this equipment can meet different needs. It not only provides efficient and precise processing but also operates reliably in various extreme environments, helping businesses reduce downtime and maintenance costs. Investing in an infrared stone cutting machine will not only enhance production capacity but also give you an edge in the competitive market.

If you have any questions about the infrared bridge stone cutting machine, or if you would like to learn more about how to choose and use this equipment, feel free to leave a comment or directly contact our team. We are here to serve you.

Leave a Comment