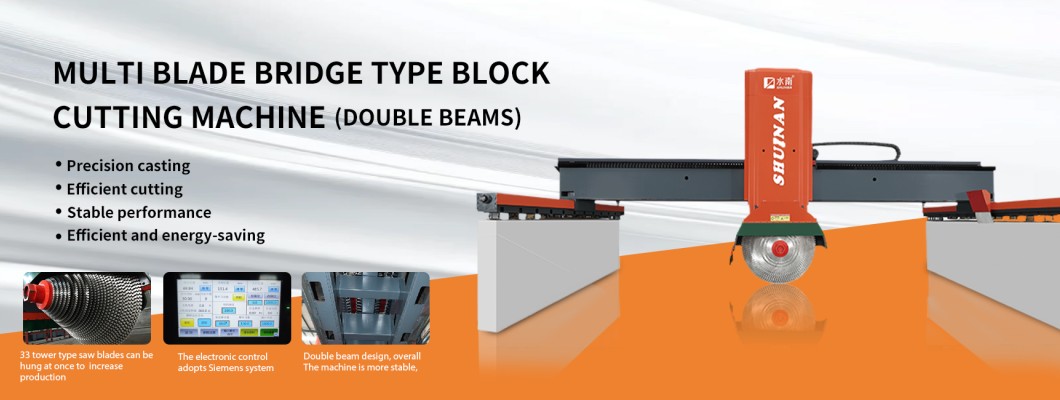

Revolutionizing Stone Processing: How Double-Beam Multi-Blade Bridge Cutting Machines Enhance Efficiency and Reduce Costs

In the modern stone processing industry, enhancing production efficiency and controlling operational costs are critical to maintaining a competitive edge. As technology advances, cutting equipment continues to evolve, playing a pivotal role in shaping both the speed and cost-effectiveness of processing operations. One such innovation that stands out is the double-beam multi-blade bridge type block cutting machine, which represents a significant leap forward in stone cutting capabilities.

This article examines how adopting cutting-edge stone machinery—particularly the double-beam multi-blade bridge block cutter—can streamline production, minimize waste, and increase profitability for stone processing businesses.

1. High-Speed Cutting for Increased Productivity

Traditional cutting machines often struggle with large stone blocks due to limited precision and slower processing speeds. These limitations can hinder production timelines and drive up operational costs.

The double-beam multi-blade bridge cutter addresses these challenges by incorporating:

- A dual-beam framework for added structural stability,

- Multiple blades that operate simultaneously to perform several cuts in one pass.

This innovative setup allows for faster, more efficient processing of large stone blocks, significantly boosting output while maintaining high precision. The ability to cut multiple slabs at once means more product in less time—translating directly into increased production capacity and lower labor costs.

Simultaneous Cutting for Maximum Output and Efficiency

Unlike traditional stone cutting machines, the double-beam multi-blade bridge block cutter is engineered to perform multiple cutting operations at once. This multi-blade capability allows factories to process a higher volume of stone blocks within the same production window, dramatically increasing overall efficiency and shortening production cycles.

By streamlining operations, this technology enables manufacturers to meet growing market demands more effectively, while also reducing labor time and resource consumption—a key advantage in today’s competitive stone processing industry.

2. Precise Cutting to Ensure Stone Quality

While boosting production speed is essential, maintaining cutting accuracy is equally critical to ensuring product quality and minimizing waste. Traditional stone cutting equipment often struggles to sustain precision under heavy workloads, resulting in irregular edges, inconsistent thickness, and increased material loss.

The double-beam multi-blade bridge cutting machine addresses these issues with:

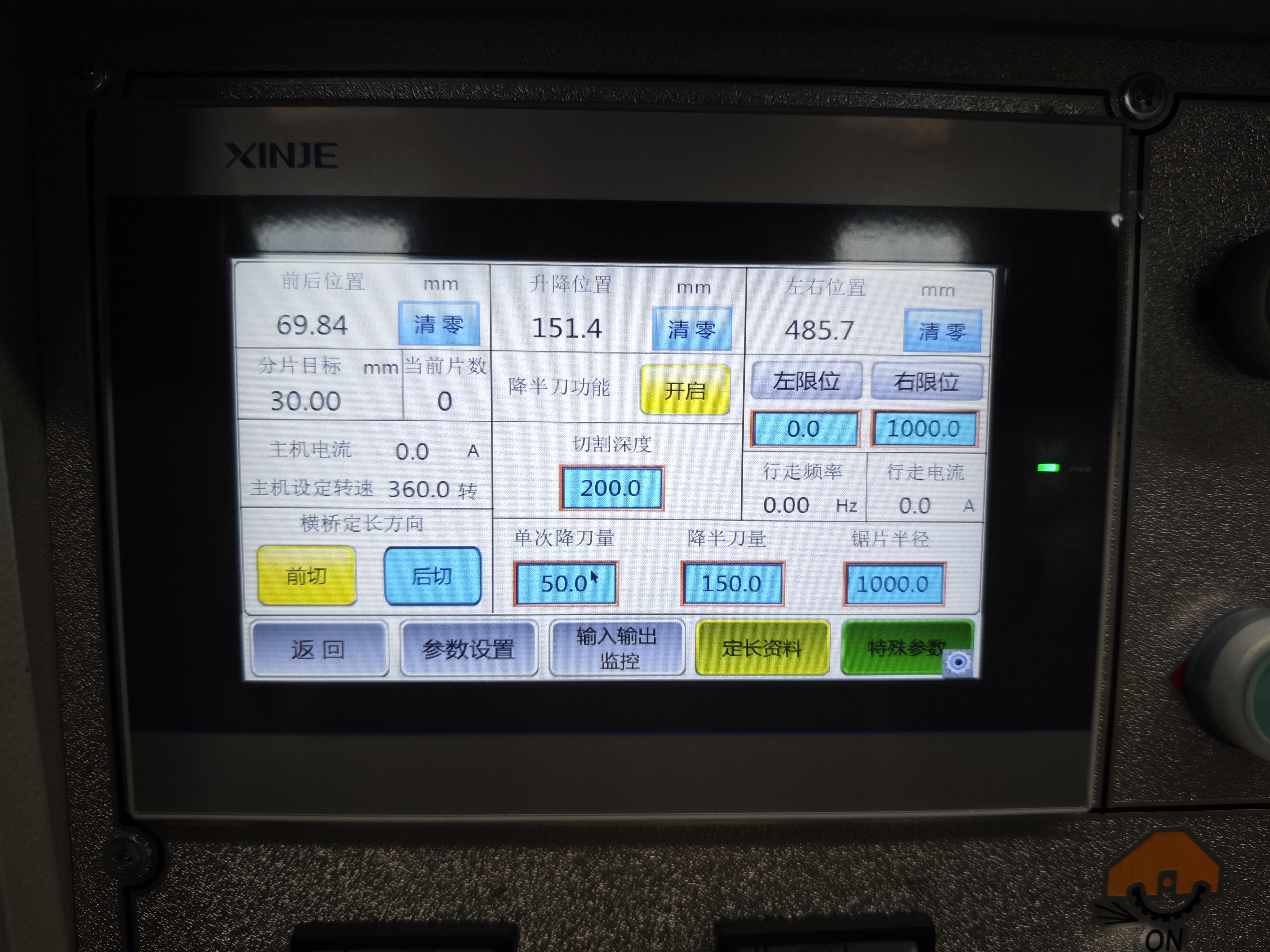

- An advanced digital control system that ensures real-time stability and precise blade positioning,

- High-precision cutting tools designed to deliver smooth, uniform cuts with minimal deviation.

This high level of accuracy not only enhances the overall quality of finished stone slabs, but also reduces costly material waste, helping manufacturers improve yield, lower rework rates, and meet demanding customer specifications with confidence.

Furthermore, the double beams multi blade bridge type block cutting machine has a reasonable and adjustable blade distribution, which ensures that each cutting surface meets perfection, reducing the burden of subsequent processing and further lowering production losses.

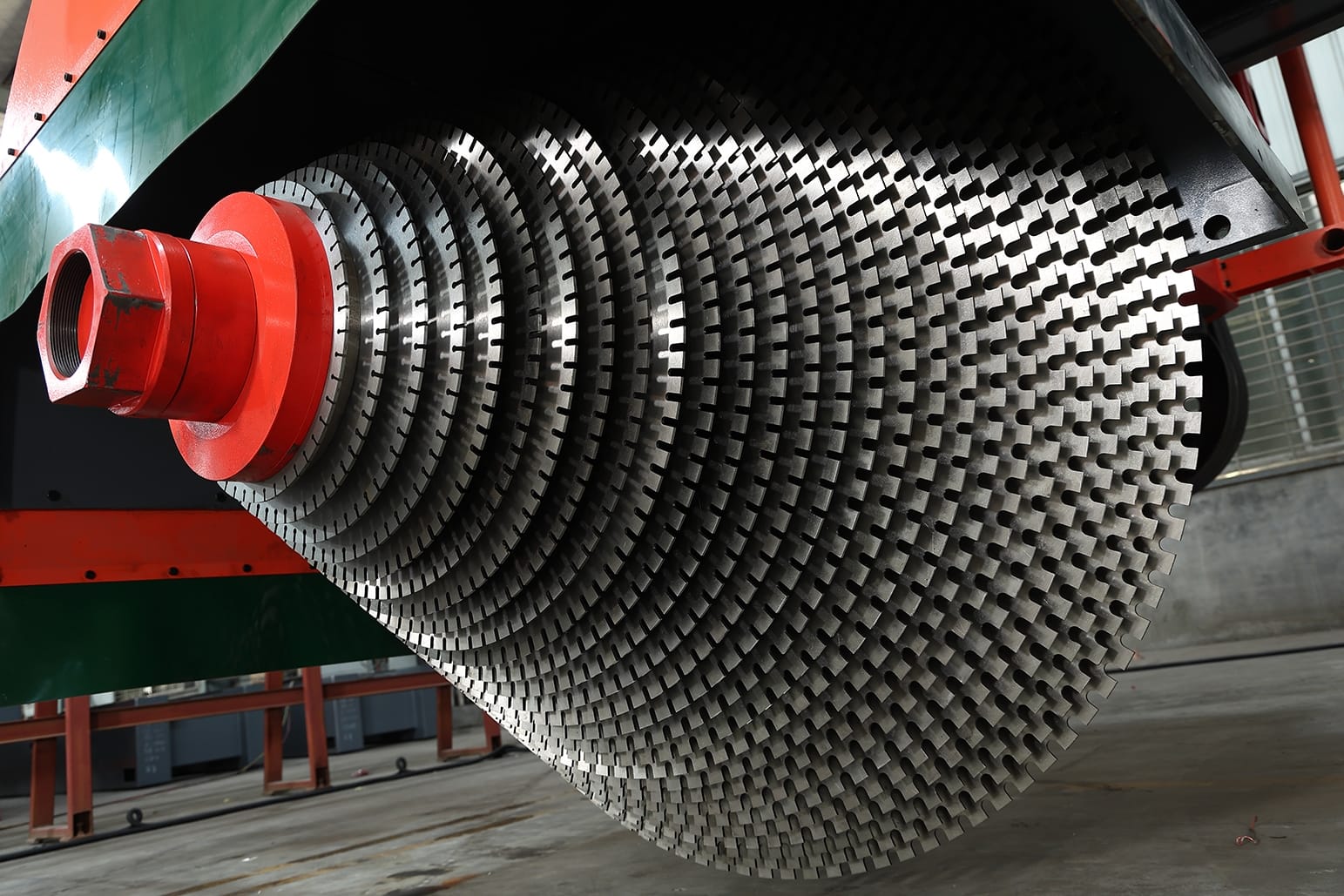

3. Multi-Blade Design to Reduce Equipment Operating Costs

One of the most prominent features of the double beams multi blade bridge type cutting machine is its multi-blade design. Traditional block cutting machines often rely on a single blade for cutting, which not only reduces efficiency but also leads to faster blade wear, increasing operating costs.

However, with the double beams multi blade bridge type cutting machine, multiple blades work simultaneously, allowing for multiple cuts per operation. This reduces blade wear and prolongs the lifespan of the equipment. Additionally, the even distribution of load during operation lowers the likelihood of mechanical failures, further reducing repair and replacement costs.

4. Saving Labor and Reducing Labor Costs

With the advancement of automation in production, the high efficiency of the double beams multi blade bridge type cutting machine also reduces the need for manual labor. Traditional stone cutting equipment requires significant manual involvement, from operating the machinery to transporting materials, which contributes to high labor costs. The double beams multi blade bridge type cutting machine, however, features an intelligent control system and automated feeding mechanism, which significantly reduces reliance on manual labor.

This increase in automation not only boosts cutting efficiency but also lightens the workload of operators, reducing the expenditure on labor costs. Moreover, since the equipment operates more stably, workers' hours are effectively saved, allowing resources to be redirected to other higher-value tasks.

5. Increased Capacity and Reduced Energy Consumption

While improving production efficiency is crucial, controlling energy consumption is equally important. The double beams multi blade bridge type cutting machine is designed with energy efficiency in mind, incorporating energy-saving motors and intelligent electronic control systems to minimize unnecessary energy wastage while ensuring efficient cutting.

In addition, the multi-blade design shortens cutting times, further reducing the load on the equipment and lowering energy consumption. These energy-saving measures not only reduce production costs but also align with modern environmental and sustainability trends.

Conclusion

By introducing advanced stone machinery, particularly the double beams multi blade bridge type cutting machine, businesses can achieve significant results in improving production efficiency, ensuring cutting quality, saving labor, and reducing energy consumption. For stone processing factories, investing in high-performance, precise, and energy-efficient equipment is key to lowering production costs and improving market competitiveness.

If you are looking for a solution to enhance production efficiency, consider our range of stone cutting machines. With their outstanding performance and cost-effectiveness, they will help elevate your business to the next level.

Leave a Comment