Hello everyone! As a business owner in the stone machinery industry for many years, I want to share some thoughts on how investing in stone machinery can significantly lower processing costs and enhance market competitiveness.

In our industry, many stone processing factories still rely heavily on manual labor for various tasks. While this method may seem traditional, it leads to inefficiency and high costs. As a stone machinery provider, I understand that automation is the key to reducing costs, improving production efficiency, and boosting a company's competitiveness. Today, I want to discuss how introducing advanced stone machinery has helped our clients reduce costs, enhance production speed, and ultimately become more competitive in the market.

1. Automation: Reducing Costs from the Start

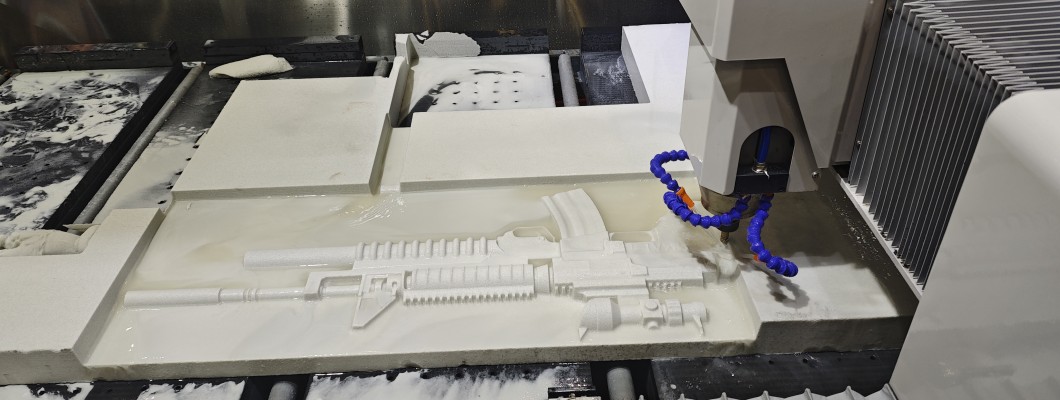

To begin with, we need to understand the high-cost areas in stone processing. Traditionally, stone cutting and finishing heavily relied on manual labor. Not only was this process slow, but the margin for error was high, leading to waste and costly rework. For instance, in our factory, cutting was done manually, which resulted in limited output and frequent mistakes, increasing material waste and extending production time. With labor costs rising year after year, relying solely on manual labor no longer met the production demand.

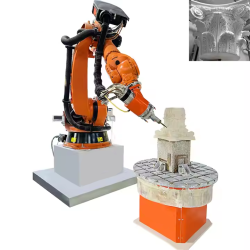

However, since we introduced automated stone cutting machines and carving equipment, everything changed. These machines have drastically increased production speed and, because of their precision, minimized material waste. In terms of raw material usage, waste has been reduced to almost zero, and efficiency has improved by over 30%. This means we can produce more products with fewer materials, directly reducing the cost per unit.

2. Lower Labor Costs and Improved Efficiency

After implementing machinery, labor costs in our factory have significantly decreased. Previously, many workers were required to operate the machines, which resulted in slower production times and higher labor management costs. Now, with advanced stone machinery, we only need a few workers to monitor and maintain the equipment, which greatly reduces the need for human labor.

In addition, machines work much faster than humans, allowing for shorter production cycles and faster delivery times. For our customers, reliable delivery and consistent quality are essential, and that's one of the direct benefits of automation.

3. Price Impact: Lowering Prices and Boosting Competitiveness

When customers choose stone products, they consider not only the quality but also the price. With the introduction of stone machinery, we’ve been able to reduce our production costs and, as a result, lower our product prices without compromising quality.

Previously, one of our products had a high price due to labor-intensive production processes, which limited sales. However, after implementing automated equipment, we reduced our production costs and increased product precision and consistency. As a result, we successfully lowered the price by around 10%, making our product more competitive in the market, which in turn led to an increase in sales.

4. Long-Term Benefits: Higher Profits and Stronger Market Position

While the immediate cost savings from automation may not be as visible, the long-term benefits are clear. Investing in machinery requires an upfront cost, but through increased production efficiency and reduced labor costs, the investment pays off in a short amount of time. Over the long term, it significantly boosts profitability.

Additionally, as market competition intensifies, automation not only provides a cost-saving solution, but it also helps to improve product quality and consistency. This is crucial for building brand reputation and establishing a strong market position.

Conclusion: Embracing the Future with Automation

As professionals in the stone machinery industry, we know that to thrive in an increasingly competitive market, relying solely on traditional manual methods and high prices is no longer enough. Modern stone machinery can help reduce production costs, enhance product quality, and improve market competitiveness.

If you’re still uncertain about investing in these high-efficiency stone processing machines, my advice is simple: don’t wait any longer—automation is the future. It will help you gain a solid foothold in this competitive market, acquire more clients, and expand your market share.

Let’s embrace stone machinery, lower costs, improve efficiency, and win the future!

Leave a Comment