How Blade Diameter Affects Cutting Depth and Stability (2000–3000mm Explained)

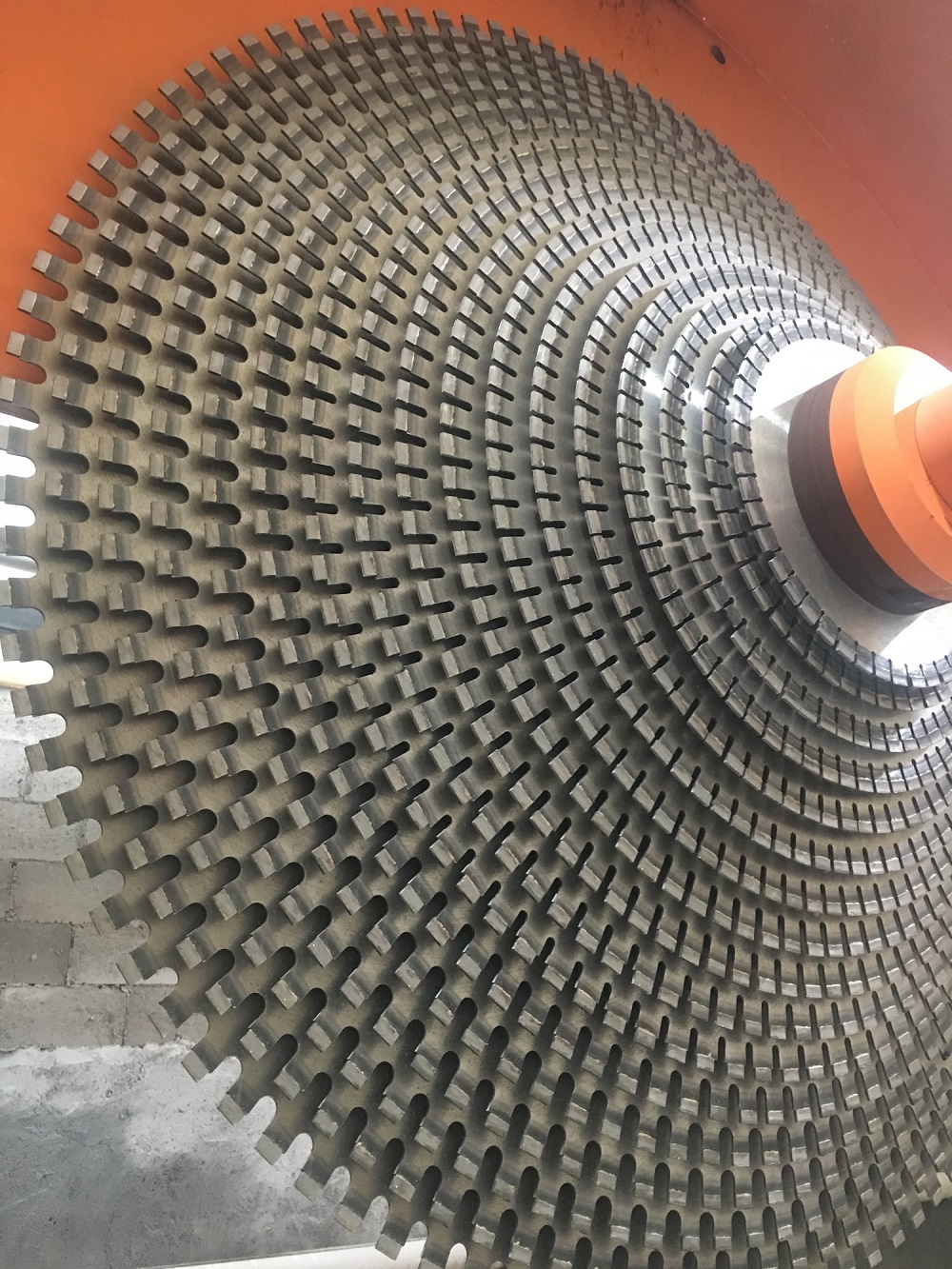

Choosing the right blade diameter is one of the fastest ways to improve block cutting efficiency and slab quality. In bridge-type block cutting (including multiblade block cutting), the diameter you select directly influences maximum cutting depth, spindle load, vibration risk, and your daily production stability.

This guide explains what changes when you move from 2000mm to 3000mm blades, what it means for real production, and how to choose a safe, practical configuration for granite and marble blocks.

1) Cutting Depth: The Most Direct Impact of Blade Diameter

Blade diameter determines how deep the blade can cut. Larger blades generally provide greater cutting depth, which is important if you regularly process taller blocks or need more clearance for certain setups.

However, deeper cutting is not the only goal. You want enough cutting depth for your typical block sizes without creating unnecessary load, vibration, or operating cost.

2) Stability and Vibration: Why Bigger Blades Need Stronger Support

As blade diameter increases, the cutting system usually faces higher vibration risk if the machine structure and spindle system are not designed for it. In simple terms: larger blades create a bigger cutting arc and higher leverage forces.

What vibration can cause

- Uneven slab thickness (tapering or thickness fluctuation)

- Chipping on edges (especially on hard granite)

- Faster blade wear and segment damage

- Lower surface quality and higher downstream polishing cost

How to keep stability with larger diameters

- Use a rigid bridge structure and stable guide rails

- Maintain spindle balance and correct alignment

- Ensure proper foundation and leveling (especially for long-term accuracy)

- Match feed speed and depth parameters to stone hardness

3) Spindle Load and Power: Diameter Changes the Cutting “Demand”

Bigger blades are heavier and usually need more torque to cut efficiently—especially in granite. If power and torque are not sufficient, operators often reduce feed speed to protect the system, which reduces real output.

When comparing blade diameter options, always consider the full system: motor power, spindle stiffness, cooling capacity, and feeding stability. A well-matched setup often delivers better output than a “bigger blade but underpowered” configuration.

4) Tool Life and Operating Cost: Bigger Is Not Always Cheaper

Blade cost and operating cost often increase with diameter. Larger blades may offer productivity benefits, but they also require careful parameter control and stable cooling to avoid overheating and abnormal wear.

Tips to protect blade life

- Keep stable water flow to every cutting zone

- Avoid “too aggressive” feed rates when cutting hard granite

- Use the right blade segment for your material

- Monitor vibration and replace worn components early

5) 2000–3000mm Blade Diameter: How to Choose in Real Projects

For many factories, the best choice depends on block height, material hardness, and your target throughput. Use these practical questions to decide:

- What is your real block height range? Choose a diameter that safely covers your maximum and typical blocks.

- Are you mainly cutting granite or marble? Granite often needs higher stability margins and power.

- Do you prioritize maximum depth or stable daily output? Stable output usually wins for long-term ROI.

- Is your workshop foundation and alignment strong enough? Larger blades benefit more from good foundation and leveling.

- Do you have reliable water and slurry management? Cooling stability matters more as cutting demand increases.

Simple recommendation logic

- 2000–2200mm: practical for many standard block sizes, easier to keep stable, lower operating cost.

- 2500–2800mm: a balanced option when you need more depth but still want strong stability.

- 3000mm: for larger/taller blocks when the machine structure, power, and foundation support high-demand cutting.

6) Common Mistakes When Choosing Blade Diameter

- Choosing maximum diameter without confirming block size reality: leads to higher cost without real benefit.

- Ignoring foundation and alignment: stability problems show up later as thickness issues or blade wear.

- Not matching parameters to material: granite and marble require different feed and cooling practices.

- Underestimating water/slurry importance: poor cooling reduces output and blade life.

7) A Quick Checklist Before You Decide

- Block size range (especially max height)

- Material type(s): granite, marble, basalt, limestone, etc.

- Target slab thickness and daily output goal

- Machine power and spindle system suitability

- Workshop conditions: foundation, leveling, water supply, slurry discharge

About Shuinan Machinery

Shuinan Machinery supplies stone processing equipment for block-to-slab production. If you share your stone type, block size range, and output target, we can recommend a practical configuration, including blade diameter selection (2000–3000mm), parameter suggestions, and workshop preparation tips.

Contact Us

Need a recommended setup for your block cutting project? WhatsApp Shuinan Machinery: +86 19805955837

Leave a Comment