Comparing Marble vs. Granite: Machinery Needs for Different Stones

Choosing the right machinery starts with understanding the stone. Marble (metamorphosed limestone, ~Mohs 3–4) is softer, more porous, and prone to edge chipping and chemical etching. Granite (igneous, ~Mohs 6–7) is harder, more abrasive, and demands higher power and tougher tooling. These differences drive decisions on saw motor sizing, machine rigidity, coolant delivery, and diamond tool bond selection.

1) Cutting & Slabbing: What Changes Between Marble and Granite

Block to slab

- Marble: Multi-wire or gang saws with finer diamond beads and lower wire tension achieve clean kerfs and minimize micro-cracks. Feed rates can be higher than granite.

- Granite: Multi-wire with harder beads and slower feeds to manage abrasion and heat; expect higher power draw and wire consumption.

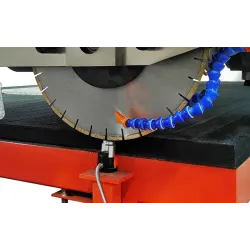

Table / bridge sawing

- Marble: Bridge saws in the ~11–15 kW main motor range are often sufficient. Machine stiffness matters, but cutting loads are lighter.

- Granite: Prefer 15–22 kW (or higher for thick stock), heavier gantry, frequency-controlled spindle, and rigid rails. Ample, well-aimed water is essential to control heat and silica dust.

Intricate shapes

- Marble: CNC bridge saws or waterjets excel at curves, inlays, and thin profiles; lower cutting forces reduce edge blow-out.

- Granite: Use waterjet or high-stiffness CNC with robust tooling; slower passes prevent micro-fractures along edges.

2) Tooling: Blades, Bits, and Bonds

- Diamond blade/segment bond rule of thumb: Use a harder bond for softer/abrasive materials (e.g., marble) so diamonds are retained longer; use a softer bond for hard materials (e.g., granite) to expose fresh diamonds.

- Router/bullnose tools: Marble sets can run higher feed with lighter pressure. Granite sets need reinforced shanks, optimized coolant, and conservative feeds to avoid chatter.

- Core drills: Marble permits higher rpm and feed; granite favors lower rpm, steady feed, and aggressive flushing.

3) Polishing & Surface Finishing

- Marble: Popular finishes include honed, polished, leathered, and antiqued. Use lower head pressure and finer grit progressions to avoid orange peel. Chemical polishing is common but requires tight control.

- Granite: Needs more power per head and stiffer platens to build gloss. Expect longer grit ladders and higher coolant volumes. Resin pads for dark granites; metal/resin combos for rapid stock removal.

4) Edge Work & Profiling

- Marble: Softer stone allows crisp ogees and deep profiles with modest spindle power; support edges to prevent blow-outs and keep tools sharp to reduce feathering.

- Granite: Requires stout spindles and rigid fixturing. Multi-pass strategies with reduced depth of cut keep edges chip-free.

5) Handling, Reinforcement & Quality Assurance

- Reinforcement: Marble often benefits from back-mesh (fiberglass) and resin impregnation, especially on veined material. Granite may use resin to fill pinholes; structural mesh is less common.

- Inspection: Marble—check for fissures/open veins before profiling. Granite—monitor micro-chips along cut edges; adjust feeds/coolant as needed.

6) Dust, Slurry & Safety

- Marble slurry (mostly CaCO3) settles more readily but still requires compliant handling and recycling.

- Granite generates fine silica—favor wet cutting and robust water recycling/filtration. Enclose polishers where possible to protect operators and the environment.

7) Power & Line Configuration (Typical)

- Marble-oriented plant: Multi-wire/gang saw → bridge saw/CNC sawjet → inline edge polisher → slab polisher (moderate kW/head). Emphasis on throughput and fine finishing; lighter motors acceptable.

- Granite-oriented plant: Multi-wire → heavy bridge saw/CNC center (≥15–22 kW spindle) → robust edge line → high-power slab polisher (higher head pressure, more heads). Emphasis on rigidity, torque, and abrasion management.

8) Quick Parameter Cheatsheet (Guidance, not specs)

- Spindle power: Marble ~11–15 kW typical; Granite 15–22 kW+ preferred for thick stock.

- Feeds/speeds: Marble supports higher feeds/lighter loads; Granite needs slower feeds/shallower passes.

- Coolant: Both require strong, well-aimed flow; Granite generally needs more volume.

- Bond choice: Hard bond ↔ soft/abrasive stone; Soft bond ↔ hard stone.

9) Common Mistakes to Avoid

- Using the same blade bond for both stones—leads to glazing (granite) or premature wear (marble).

- Under-powering granite saws—causes stalling, overheating, and poor edges.

- Over-pressuring marble during polishing—induces orange peel and swirls.

- Inadequate water management—chips rise, pads burn, silica risk increases.

- Skipping reinforcement on veined marble before thin profiling.

10) Buying Checklist (Marble vs. Granite)

- Machine rigidity: Gantry weight, guideway type, table flatness.

- Motor & inverter sizing: Ensure torque for granite; VFD for fine control.

- Coolant delivery: Adjustable nozzles, flow capacity, filtration/recycling readiness.

- Tool compatibility: Blade arbor sizes, router tooling systems, quick-change spindles.

- Automation: Laser templating, camera nesting, probing, PLC/CNC ease of use.

- Service & spares: Stocked consumables (blades, pads, beads), local response times.

Final Thoughts

Marble and granite ask different things from your equipment. Match power, rigidity, tooling bond, and polishing strategy to the material, and you’ll get cleaner edges, faster cycles, and longer tool life. If you run both stones, plan for tooling swaps, programmable feeds, and water management that accommodates granite’s abrasion and marble’s finish sensitivity.

Contact Shuinan Machinery

Website: www.shuinanmachinery.com

WhatsApp: Click to chat on WhatsApp

Leave a Comment