Single-Blade vs Multi-Blade Stone Cutting: What’s the Difference?

Choosing the right stone cutting method is a crucial decision for stone processing factories. One of the most common questions is whether to use single-blade or multi-blade stone cutting machines.

Both methods are widely used in stone processing, but they serve different production needs. Understanding their differences can help factory owners improve efficiency, reduce costs, and achieve better cutting results.

What Is Single-Blade Stone Cutting?

Single-blade stone cutting uses one saw blade to cut through a stone block, producing slabs one cut at a time. This method is commonly found in smaller factories or operations with lower production volume.

Single-blade cutting offers flexibility and simpler operation, making it suitable for processing different stone sizes and materials with frequent adjustments.

Main Characteristics of Single-Blade Cutting

- One blade cuts one slab at a time

- Lower initial machine investment

- Flexible for small-batch production

- Lower daily output

What Is Multi-Blade Stone Cutting?

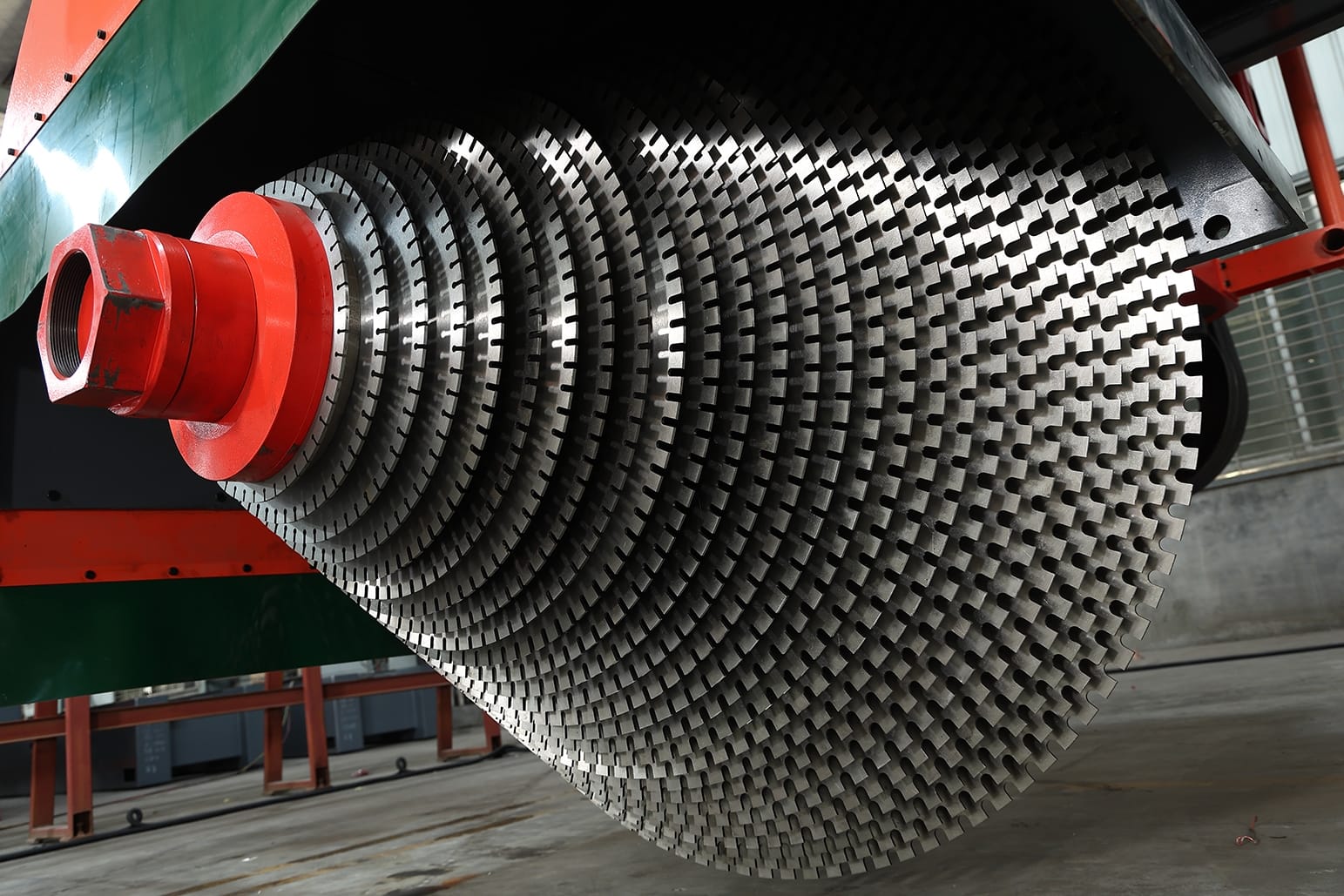

Multi-blade stone cutting uses multiple saw blades mounted on a single cutting bridge, allowing multiple slabs to be cut from a stone block in one cutting cycle.

This method is widely used in medium to large-scale stone factories where production efficiency and consistent slab quality are priorities.

Main Characteristics of Multi-Blade Cutting

- Multiple slabs cut simultaneously

- Higher daily production capacity

- More consistent slab thickness

- Reduced labor dependency

Key Differences Between Single-Blade and Multi-Blade Cutting

| Aspect | Single-Blade Cutting | Multi-Blade Cutting |

|---|---|---|

| Cutting Method | One blade, one cut at a time | Multiple blades, multiple cuts simultaneously |

| Production Efficiency | Low to medium | High |

| Labor Requirement | Higher | Lower |

| Slab Consistency | Depends on operator skill | Highly consistent |

| Suitable Factory Size | Small or flexible production | Medium to large-scale production |

Which Cutting Method Is More Efficient?

In most cases, multi-blade stone cutting is significantly more efficient for factories with stable and continuous production. Instead of increasing cutting speed with a single blade, multi-blade systems improve efficiency by cutting more material at the same time.

Single-blade cutting remains useful for special shapes, small orders, or frequent production changes, but it is less suitable for high-volume slab production.

How Multi-Blade Cutting Reduces Production Costs

By producing more slabs per cutting cycle, multi-blade cutting reduces:

- Cost per slab

- Labor cost per unit

- Machine operating time per slab

- Blade wear caused by unstable cutting

This makes multi-blade cutting a cost-effective solution for long-term production.

Application Scenarios

Single-Blade Cutting is suitable for:

- Small factories or workshops

- Customized or small-batch orders

- Frequent changes in stone size

Multi-Blade Cutting is suitable for:

- Medium and large stone processing factories

- Continuous slab production

- Granite and marble block cutting

- Factories focusing on efficiency and consistency

Conclusion

Understanding the difference between single-blade and multi-blade stone cutting helps factory owners choose the right cutting solution for their production needs.

While single-blade cutting offers flexibility, multi-blade cutting delivers higher efficiency, better consistency, and lower long-term production costs for most stone processing factories.

About Shuinan Machinery

Shuinan Machinery is a professional manufacturer of stone processing machinery, specializing in reliable and efficient cutting solutions.

Our multi-blade bridge stone cutting machines are designed to meet the demands of modern stone factories, providing stable performance and high productivity in real production environments.

Contact Us

If you are considering upgrading your stone cutting process or would like professional advice, feel free to contact us.

WhatsApp: +86 198 0595 5837

Leave a Comment