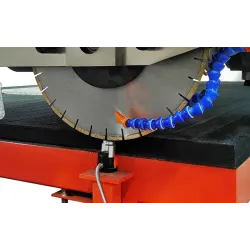

In the process of stone processing, stone cutting machines are indispensable. The main types of cutting machines used include bridge - type cutting machines and infrared stone cutting machines.

A stone cutting machine is a mechanical equipment specially designed for cutting non - metallic brittle materials such as marble, granite, and tiles. Its core function is to achieve efficient and precise cutting through technologies like diamond saw blades or high - pressure water jets. In short, it is a core device in the stone processing field, which divides materials through mechanical force or fluid power, significantly improving production efficiency and material utilization.

Before operation, one should have a certain understanding of the operation procedures of stone cutting machines and the accessories of profile cutting machines.

(1). Before Work

1. Put on work clothes and safety goggles. Female workers with long hair should tie up their hair and wear a work cap.

2. Conduct a detailed inspection of the power knife - switch, the tightness of the saw blade, the saw blade guard, the cutting machine, or the safety baffle. The operating table must be stable for laser cutting machines. Sufficient lighting is required for night operations.

3. Turn on the main switch and let the machine run idle for a few turns. Only after confirming safety is it allowed to start.

(2). During Work

1.It is strictly prohibited to operate with gloves on. If dust is generated during operation, wear a mask or face shield.

2.Do not attempt to cut small workpieces that are not clamped tightly.

3.This cutting machine is only allowed to cut profiles.

4.Do not perform forced cutting operations. Make sure the motor reaches full speed before cutting.

5.No one is allowed to stand behind the saw.

6.Do not lean over or go around the saw machine. Do not release either hand or raise your arm from the saw or the workpiece until the saw blade stops.

7.o not operate when the guard is not in place. Do not place your hands within 15 centimeters of the saw blade or the belt sander.

8.Before maintenance or replacement of accessories, the power must be cut off first, and wait until the saw blade stops completely.

9.If an abnormal sound is detected, stop immediately for inspection.

(3). After Work

1.Turn off the main power supply.

2.Clean and tidy up the operating table and the work site.

(4). In case of personal injury or equipment accidents, keep the scene intact and report to the relevant departments.

Stone cutting machines play an irreplaceable role in stone processing. However, problems during their use are quite common. The most common ones are accidentally cutting the stone too small, too large, or off - center, which increases the production costs of enterprises. Also, during the use of stone cutting machines, proper maintenance is required. Otherwise, improper operation or lack of maintenance may lead to damage to the cutting machines. Once damage occurs, high repair costs will be incurred.

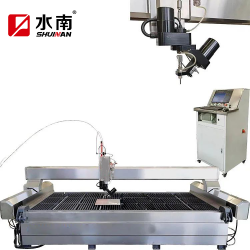

ShuiNan Machinery, co., Ltd: Pioneering Excellence in Global Manufacturing. Including Mine working equipment, Stone quarry Machine, Stone sharping machine, etc.

Covering an impressive 70000㎡(105 acres), ShuiNan Machinery, co.Ltd stands as a powerhouse within the global machinery sector. Ranked among the top 100 mechanical industry leaders worldwide, ShuiNan is celebrated for its cutting-edge technology and innovation. With a commitment to excellence, we set benchmarks in mechanical engineering, leading the industry with unparalleled advancements.

ShuiNan Machinery, Co.,Ltd, we don't just manufacture; we engineer the future.

Leave a Comment