In-Depth Analysis of the Stone Machinery Industry in 2025: Automation and Intelligence Leading the Way

By Shuinan Machinery | June 21, 2025

1. Market Overview

The global stone machinery industry is evolving rapidly. Recent studies report:

- Stone Cutting Machines: Valued at USD 4 billion in 2023, forecasted to hit USD 5.94 billion by 2030 (CAGR 5.8%).

- Stone Crushing Equipment: Estimated at USD 2.24 billion in 2024, projected to reach over USD 3.2 billion by 2030.

- Automated Processing Systems: Experiencing annual growth rates over 25%, driven by smart manufacturing demand.

2. Key Growth Drivers

- Infrastructure Boom: Urban redevelopment and public works drive equipment demand.

- Localized Manufacturing: Europe and North America are reshoring production, increasing equipment purchases.

- Rising Labor Costs: Encouraging adoption of robotics and CNC systems.

- Environmental Standards: Demand for energy-efficient motors and intelligent dust control systems is growing.

3. Technology Trends

1) 5-Axis CNC Bridge Cutting

Supports complex cutting angles and shapes—perfect for luxury stone applications.

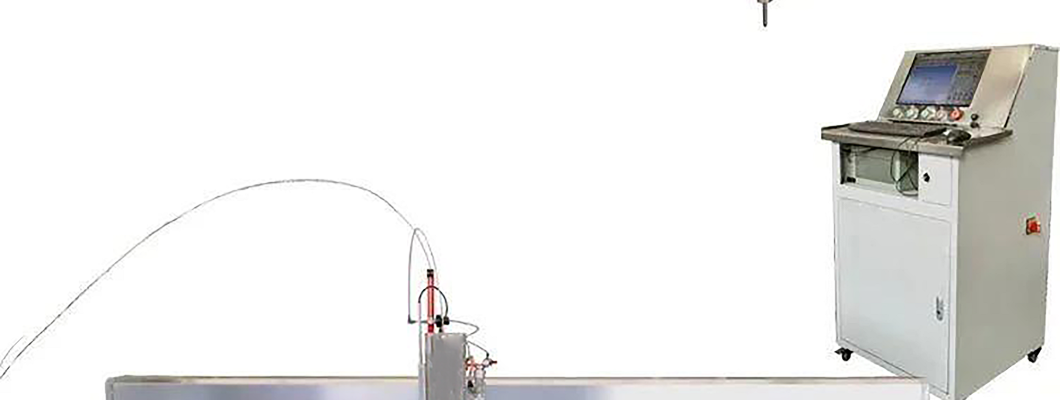

2) Ultra-High Pressure Waterjet

Cold cutting with no thermal distortion, ideal for inlays and thin slabs.

3) AI Nesting Systems

Combines visual scanning with AI to reduce material waste by up to 12%.

4) Smart Production Lines

Full-line automation with PLC and SCADA systems ensures seamless, scalable production.

4. Applications

- Facade and exterior wall cladding

- Kitchen countertops and bathroom vanities

- High-end interior panels and flooring

- Monuments and public sculpture art

5. Selection Guide

- Material Type: Granite requires high-speed spindles; marble suits waterjets.

- Production Volume: Under 100,000 m²/year: bridge saws; above 300,000 m²: full-line automation.

- After-Sales Support: Choose suppliers with local service and spare part warehouses.

- Total Cost of Ownership: Include electricity, tool life, downtime, and consumables.

6. Case Study

An Italian luxury countertop manufacturer introduced 5-axis bridge saws and robotic handling, achieving:

- 35% increase in labor productivity

- 9% improvement in stone utilization

- EUR 180,000 saved annually in raw material

7. Future Outlook

By 2033, the stone processing equipment market may exceed USD 13 billion. Major opportunities lie in:

- Ultra-Thin Stone Processing: Promotes high-precision and energy-efficient cutting systems.

- Service-Based Manufacturing: Includes training, remote support, and SaaS-based tools.

- Digital Integration: IoT, cloud analytics, and AI-driven optimization are becoming standard.

Leave a Comment