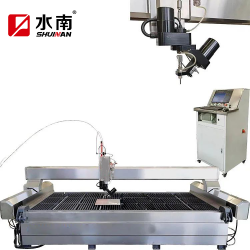

Machine Overview - Automatic Granite Polishing Line Machine 20C

Our granite polishing machine is engineered for high-volume processing in quarries and stone factories. Designed for industrial-scale operations, it ensures consistent, high-quality finishes on granite slabs.

Technical Specifications

| Parameter | Value | Unit |

|---|---|---|

| Belt transfer speed | 0-4000 | mm/min |

| Machine Length | 10200 | mm |

| Machine Width | 2150 | mm |

| Machine Height | 2200 | mm |

| Power of spindle motor | 7.5x16 + 9x4 | kw |

| Quantity of polishing head | 20 | pcs |

| Total power | 168 | kw |

| Useful working thickness | 10-50 | mm |

| Useful working width | 1200 | mm |

| Water consumption | 23 | m³/h |

| Approximate Weight | 21000 | kg |

Real Performance Data (Daily Output)

| Parameter | Value | Unit |

|---|---|---|

| Production | 4800-6000 | m²/day |

| Power Consumption | 3360 | kWh/day |

| Water Consumption | 460 | m³/day |

Note: The above data is summarized based on the production conditions of our other customers' factories. Actual output and water/electricity consumption depend on the actual production conditions of each factory.

Water Recycling: Production water can be recycled after sedimentation and filtration through multi-level water tanks.

Why Choose Our Factory Use Granite Polishing Machine?

29 Years of Excellence

Established in 1996, trusted by customers in 50+ countries

International Certifications

ISO 9001:2015 & CE certified, meeting global standards

Expert R&D Team

Professional engineers with 20+ years industry experience

Customized Solutions

Tailored machinery for your specific quarry conditions

Lifetime Support

24/7 after-sales service & comprehensive technical training

Premium Quality

High-grade materials and strict quality control ensure superior performance and durability

Fast Delivery

Efficient logistics network ensuring quick delivery to over 50 countries worldwide

Innovation Leader

Continuous R&D investment in advanced stone processing technology and automation

Transform Your Production with Our Factory Use Granite Polishing Machine

Before: Traditional Polishing Methods

- Low Efficiency: Manual or semi-automatic methods result in slow polishing speeds and inconsistent glossiness.

- High Labor Costs: Requires multiple skilled operators, increasing operational expenses.

- Inconsistent Quality: Prone to errors, resulting in uneven shine, scratches, and lower-quality finished products.

- High Abrasive Consumption: Inefficient use of polishing abrasives leads to higher consumable costs.

After: Using Shuinan's Granite Slab Polishing Machine

- 400% Increase in Productivity: Achieve a high-gloss finish at rapid speeds, drastically boosting your output.

- Reduced Labor by 60%: Fully automated systems require minimal supervision, freeing up your workforce for other tasks.

- Superior Finish: Advanced PLC control ensures a flawless, mirror-like polish every time, enhancing product value.

- Optimized Abrasive Use: Smart system reduces abrasive consumption by up to 20%, lowering operational costs.