Are there any environmental impacts when using a Granite CNC Machine?

Hey there! As a supplier of Granite CNC Machines, we at Shuinan Machinery are often asked about the environmental impacts of using these machines. Here’s a clear, practical overview to help you operate responsibly while keeping quality and efficiency high.

What is a Granite CNC Machine?

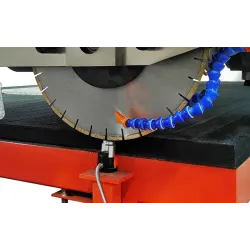

It’s a high-tech system that uses computer numerical control (CNC) to cut, shape, and polish granite with high precision. Because of their accuracy and repeatability, Granite CNC Machines are popular across the stone-processing industry for countertops, monuments, façades, and custom décor.

1. Noise Pollution

Granite CNC operations can be loud—tool engagement, spindle motors, pumps, and material handling all contribute to ambient noise. In facilities near residential or noise-sensitive areas, this can cause stress, hearing issues, or sleep disturbances for neighbors.

How to reduce it:

- Install sound-proof enclosures around cutting zones and pumps.

- Use noise-absorbing wall or ceiling panels and seal gaps around doors.

- Maintain bearings, belts, and spindles regularly to keep them quiet.

- Operate machines during reasonable hours and provide hearing protection for workers.

2. Dust Emissions (Silica)

Dry cutting or polishing generates fine respirable dust that poses health risks such as silicosis. These particles can also settle on nearby surfaces and pollute indoor air.

Solutions:

- Use source-capture dust collection systems near the cutting tool.

- Prefer wet cutting or misting to trap dust at the source.

- Employ HEPA filters in air recirculation systems.

- Maintain a clean workspace and provide PPE masks for operators.

3. Energy Consumption

Granite CNC Machines consume significant power for spindles, drives, pumps, and vacuums. If powered by fossil-fuel-based grids, this adds to greenhouse gas emissions.

Ways to improve efficiency:

- Use energy-efficient motors and drives.

- Add smart idle or standby functions when machines are not cutting.

- Optimize toolpaths to reduce cycle time.

- Combine with solar energy or off-peak power schedules to lower costs and emissions.

4. Water Usage

Water acts as a coolant and lubricant in cutting and polishing. However, excessive use can strain local water resources and create wastewater challenges.

Water-saving methods:

- Implement closed-loop water recycling systems with filters and settling tanks.

- Treat slurry and reuse water multiple times.

- Maintain filtration regularly to ensure smooth flow.

- These systems not only save water but also reduce operating costs and waste.

5. Waste Generation

Granite CNC operations create offcuts, slurry, used tools, and filters. If discarded carelessly, they occupy landfill space and may cause contamination.

Waste management tips:

- Plan slab layouts carefully to maximize yield and minimize leftovers.

- Recycle offcuts as construction aggregates or decorative materials.

- Refurbish cutting tools when possible.

- Separate recyclable materials and follow local disposal regulations.

Our Commitment to the Environment

At Shuinan Machinery, we’re committed to making stone processing more sustainable. Our machines are designed with:

- Energy-efficient components

- Integrated dust capture systems

- Closed-loop water recycling solutions

We also provide training and support to help our customers operate efficiently and safely.

Related Products

- Italy Bridge Saw Machine – high precision and reliable cutting performance.

- CNC Processing Machinery – versatile for cutting, profiling, polishing, and engraving.

- Bridge Saw Machine – robust design for continuous stone processing.

Let’s Talk

Want to make your stone workshop greener and more efficient? Contact Shuinan Machinery today for expert advice on machine selection, dust and water control systems, and energy-saving solutions.

Phone: +86 19805955837

References

- “Environmental Impacts of Industrial Machinery” – Journal of Environmental Science and Technology

- “Sustainable Practices in the Stone-Processing Industry” – International Stone Association Report

- “Reducing Energy Consumption in CNC Machines” – Manufacturing Technology Review

© Shuinan Machinery. All rights reserved. Phone: +86 19805955837

Leave a Comment