How to Reduce Energy Use on a 5-Axis CNC Bridge Saw

Improving the energy efficiency of a 5-Axis CNC bridge saw is good for the planet and your bottom line. As a supplier at Shuinan Machinery, we’ve distilled field-proven methods that lower kWh per part while preserving accuracy and throughput.

1) Where The Power Goes

A typical bridge saw’s energy draw is concentrated in four areas:

- Spindle — highest continuous load during cutting.

- Servo axes — dynamic moves, positioning and rapid traverses.

- Pumps & auxiliaries — coolant/water, vacuum, hydraulics.

- Controls & peripherals — CNC, HMIs, lighting, conveyors.

Understanding this split helps you pick the right optimizations.

2) Quick Wins (Low Cost, Fast Payback)

- Enable auto-standby/auto-shutdown when idle; avoid running pumps and spindle at no-load.

- Right-size pump pressure/flow to the job instead of “always max.”

- Use variable frequency drives (VFDs) on pumps/fans so they scale with demand.

- Batch jobs to reduce warm-up/cool-down cycles and fixture changeovers.

3) Choose the Right Machine & Options

When specifying equipment, avoid oversizing. Look for:

- IE3/IE4-grade motors for spindle and pumps.

- High-efficiency servo drives with energy recovery (regenerative braking).

- Lightweight moving structures to reduce acceleration loads.

- Sealed, low-friction guides and optimized lubrication systems.

Shuinan Machinery can configure energy-efficient motor/drive packages to match your slab sizes and cycle profiles.

4) Optimize Cutting Parameters

Toolpath choices strongly affect energy per cut:

- Use data-driven feeds/speeds to minimize time-in-cut without overloading the spindle.

- Prefer constant chip load strategies; avoid aggressive depth that forces pump/spindle peaks.

- Shorten rapids and air-cuts via nesting and sequencing of parts on the slab.

- Adopt adaptive strategies for variable thickness or hard inclusions to prevent current spikes.

5) Tooling & Coolant Efficiency

- Select low-cutting-force blades matched to granite/marble/quartz; sharp tools cut faster with less amperage.

- Maintain coolant cleanliness; clogged lines raise pump load and heat.

- Use closed-loop water recycling with proper filtration to stabilize flow and reduce pump energy.

6) Preventive Maintenance That Saves kWh

- Keep ways and ballscrews aligned and lubricated to cut friction losses.

- Replace worn belts/bearings; drag adds current draw and heat.

- Verify phase balance and power quality; poor power factor costs money.

- Calibrate pumps and regulators so “setpoint drift” doesn’t inflate usage.

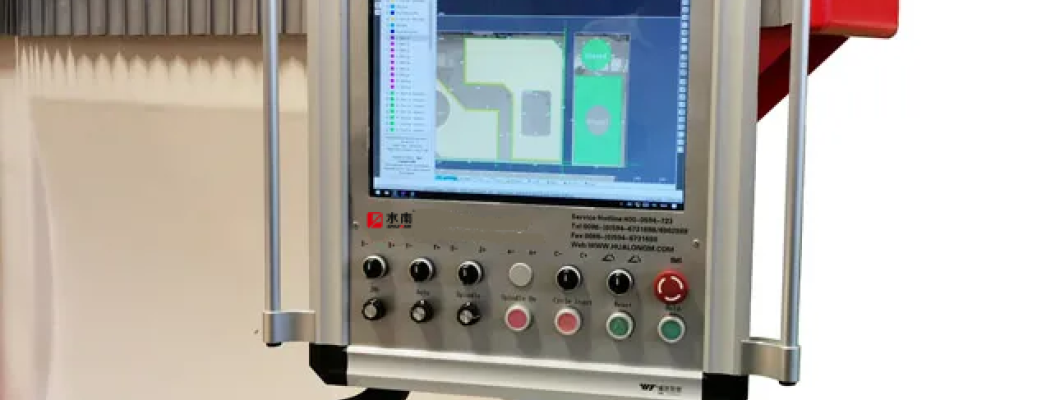

7) Smart Controls & Energy Management

- Log kWh per job and per material to identify high-cost recipes.

- Schedule heavy cuts on off-peak tariffs where available.

- Integrate MES/CNC dashboards to surface idle time, air-cuts, and standby leakage.

- Use power caps (soft limits) for non-critical operations to avoid peak demand charges.

8) Facility-Level Measures

- Add on-site solar or green PPAs to decarbonize consumption.

- Upgrade compressed air (if used) for leaks and pressure optimization.

- Improve lighting with LEDs and task lighting near the saw.

9) Train Operators for Energy-Aware Running

- Standardize setup and warm-up to avoid unnecessary spindle/pump time.

- Educate on blade selection, feeds/speeds, and coolant flow targets.

- Encourage reporting of abnormal vibrations/heat that often signal energy waste.

10) Complementary Equipment Choices

Pairing your saw with efficient equipment can multiply savings:

- Water recycling/clarifiers that match peak flow reduce pump load and water bills.

- Efficient finishing cells (e.g., countertop or sink cut-out stations) to shorten total line time.

Environmental & Business Benefits

Lower energy per slab means fewer emissions, reduced operating cost, and more stable process temperatures—often improving cut quality and tool life.

Checklist: Track These KPIs

- kWh per slab (by material and thickness)

- Average spindle current in cut

- Pump power vs. flow/pressure setpoints

- Idle/standby percentage of shift

- Tool life (m² per blade) vs. energy used

Conclusion

Energy optimization is a series of small, compounding wins—right-sized hardware, smarter toolpaths, disciplined maintenance, and engaged operators. Shuinan Machinery can help you specify efficient motor/drive options, tune process parameters, and design closed-loop water systems that cut both kWh and operating costs.

Contact Shuinan Machinery

Want a tailored energy-saving plan for your 5-Axis CNC bridge saw and supporting line? Message us on WhatsApp and we’ll size the solution to your throughput and materials.

Leave a Comment