The Future of CNC Machines in the Stone Industry: Trends and Innovations

The stone industry has seen massive advancements over the years, with the introduction of CNC (Computer Numerical Control) machines playing a crucial role in revolutionizing stone cutting, shaping, and polishing. As technology continues to evolve, the future of CNC machines in the stone industry looks even more promising. In this article, we’ll explore some of the key trends and innovations shaping the future of CNC technology in stone processing.

1. Increased Automation and Efficiency

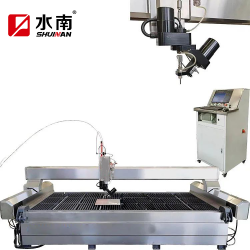

One of the most significant trends in the stone industry is the move toward greater automation. CNC machines are becoming smarter, faster, and more efficient, thanks to advancements in artificial intelligence (AI) and machine learning. These technologies allow CNC machines to learn and adapt to different materials, optimizing cutting paths and speeds for maximum productivity.

At Shuinan Machinery, we are investing in smart CNC machines that feature integrated sensors and software to analyze the material and adjust the cutting process in real-time. This not only improves cutting speed and accuracy but also reduces material waste, making operations more sustainable and cost-effective.

2. Precision and Customization

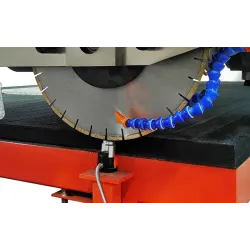

Precision is key in the stone industry, and CNC machines are continuously improving in this regard. Whether it’s for intricate carvings, custom countertops, or large architectural pieces, CNC machines can deliver the highest levels of precision, ensuring that every cut is perfect.

Additionally, as demand for customized stone products increases, CNC machines are becoming more versatile. With the ability to easily reprogram and modify machine settings, these machines are ideal for producing bespoke pieces, whether it’s custom-sized slabs, engraved designs, or complex textures.

3. Integration with 3D Modeling and CAD Software

In the past, stone cutting and shaping required a significant amount of manual effort, especially for complex designs. However, with the rise of 3D modeling and Computer-Aided Design (CAD) software, CNC machines can now directly integrate with these tools. This integration allows for a seamless transfer of designs from digital models to physical cuts, reducing the margin for error and improving overall efficiency.

At Shuinan Machinery, we offer CNC machines that are fully compatible with the latest CAD and CAM (Computer-Aided Manufacturing) systems, enabling our clients to easily produce precise stone designs with minimal manual intervention.

4. Sustainability and Eco-Friendly Practices

As the stone industry faces increasing pressure to adopt sustainable practices, CNC machines are playing a pivotal role in reducing waste and improving environmental performance. With better precision, CNC machines ensure that stones are cut with minimal waste, and the use of high-efficiency motors and energy-saving features contributes to reducing overall energy consumption.

Furthermore, advancements in water recycling systems in CNC machines are helping reduce water consumption, making stone cutting operations more eco-friendly. Shuinan Machinery is committed to integrating sustainable technologies into our CNC machine designs, helping our customers meet both production goals and environmental regulations.

5. The Rise of Robotics in Stone Processing

As robotics technology advances, it’s becoming an essential component of stone processing. Robotic arms integrated with CNC machines are being used for tasks such as handling heavy stone slabs, loading/unloading, and polishing. These robots work alongside CNC machines to automate repetitive tasks, improving both safety and efficiency in stone processing operations.

Shuinan Machinery is currently exploring how robotics can further enhance stone processing workflows, reducing labor costs and improving overall productivity in the long run.

6. Smart Maintenance and Predictive Analytics

Predictive maintenance is another exciting innovation in CNC machines. By using sensors and real-time data analysis, CNC machines can predict when a part will wear out or when maintenance is needed. This proactive approach reduces downtime, extends the life of the machine, and improves operational efficiency.

Shuinan Machinery’s CNC machines come equipped with smart diagnostic tools that monitor machine performance and alert operators to potential issues before they lead to costly repairs.

Conclusion

The future of CNC machines in the stone industry is bright, with continuous advancements in automation, precision, sustainability, and smart technologies. As the demand for custom and high-quality stone products increases, CNC machines will play an even more significant role in shaping the future of stone processing.

At Shuinan Machinery, we are committed to staying at the forefront of these innovations, providing our clients with the most advanced and efficient stone processing solutions. Whether you are looking to enhance your current operations or invest in new technologies, our team is here to help you make the best choice for your business.

Contact Us

Ready to learn more or discuss your stone processing needs? Feel free to contact us for more information or to get a personalized quote.

Leave a Comment