Boosting Productivity with an Automatic Granite Polishing Machine: A Practical Guide for Stone Processors

In modern stone factories, productivity is no longer just about running more hours. It is about using the right equipment to get more polished granite slabs out of the same workshop, with fewer workers, less downtime and more consistent quality. This is where an automatic granite polishing machine becomes a key investment.

Shuinan Machinery, founded in 1997 in the Chinese stone capital Shuitou, focuses on developing and manufacturing advanced stone processing equipment. With a 60,000 m² factory, more than 300 professional staff and an annual capacity of around 3,000 sets of machines, Shuinan Machinery supplies granite polishing lines and other stone machinery to customers in more than 30 countries worldwide.

Why Productivity Matters in Granite Slab Processing

For stone processors, the polishing line is often the bottleneck of the whole factory. If polishing is slow, unstable or heavily dependent on manual work, you will face:

- High labor cost and difficulty in training skilled workers

- Inconsistent slab quality, gloss and flatness

- Frequent downtime and maintenance interruptions

- Higher energy consumption per square meter of polished slab

An automatic granite polishing machine is designed to solve these problems by providing a continuous, stable and highly controlled polishing process.

How an Automatic Granite Polishing Machine Boosts Productivity

1. Continuous Automatic Polishing Process

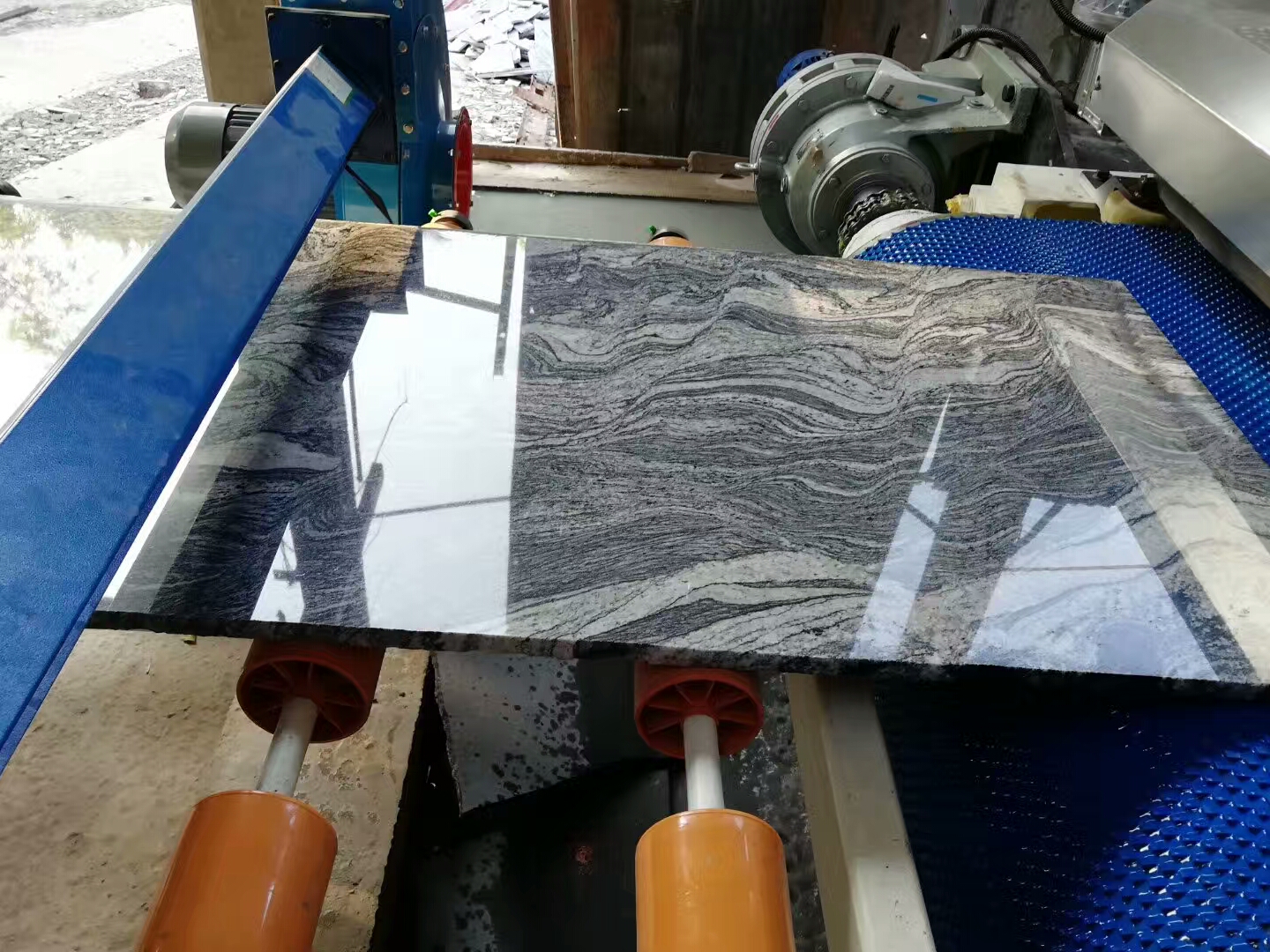

Shuinan Machinery’s automatic granite polishing machine is developed based on advanced Italian design concepts and an integrated electric control system. It is built for automatic continuous polishing of granite slabs using ordinary resin abrasive discs or triangle abrasives. Once the slabs are loaded onto the conveyor, the machine carries out the polishing process automatically with minimal manual intervention.

This continuous operation greatly reduces idle time between slabs and allows factories to handle large volumes of granite every day.

2. Stable Performance with Low Failure Rate

The machine features a modern, robust structure and an advanced operation control system. By using high-quality mechanical components and a well-designed transmission system, the polishing line offers:

- Stable running at high speed

- Low failure rate and reduced unexpected stoppages

- High efficiency with low energy consumption

For a stone factory, fewer breakdowns mean more working hours and higher output from the same equipment.

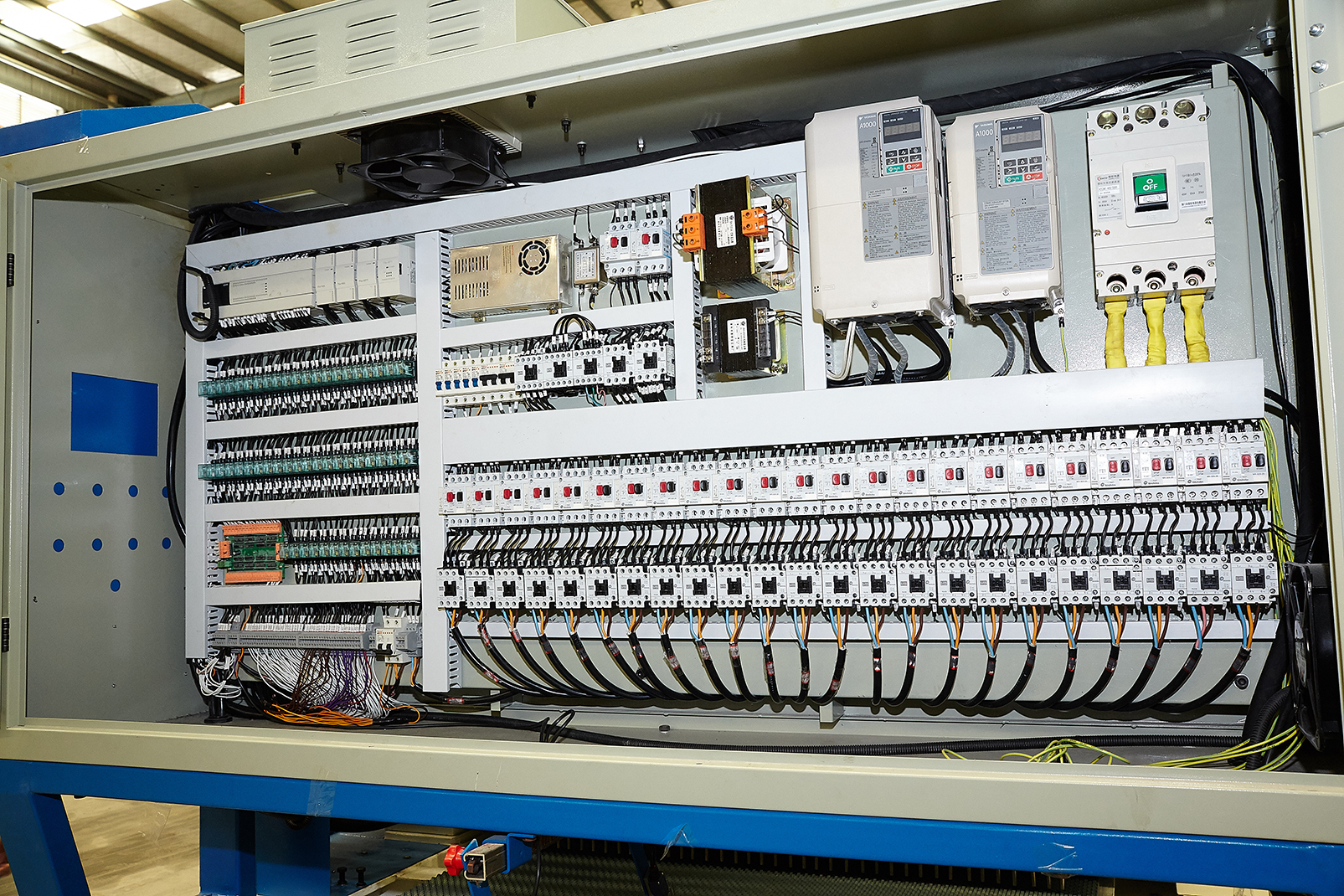

3. High-Quality Components for Long Service Life

The main structural parts are made of high-quality cast steel. Electrical components, motors and speed reducers are selected from well-known Japanese, German or other reputable brands. This combination improves reliability and extends service life, which is critical for factories running multiple shifts.

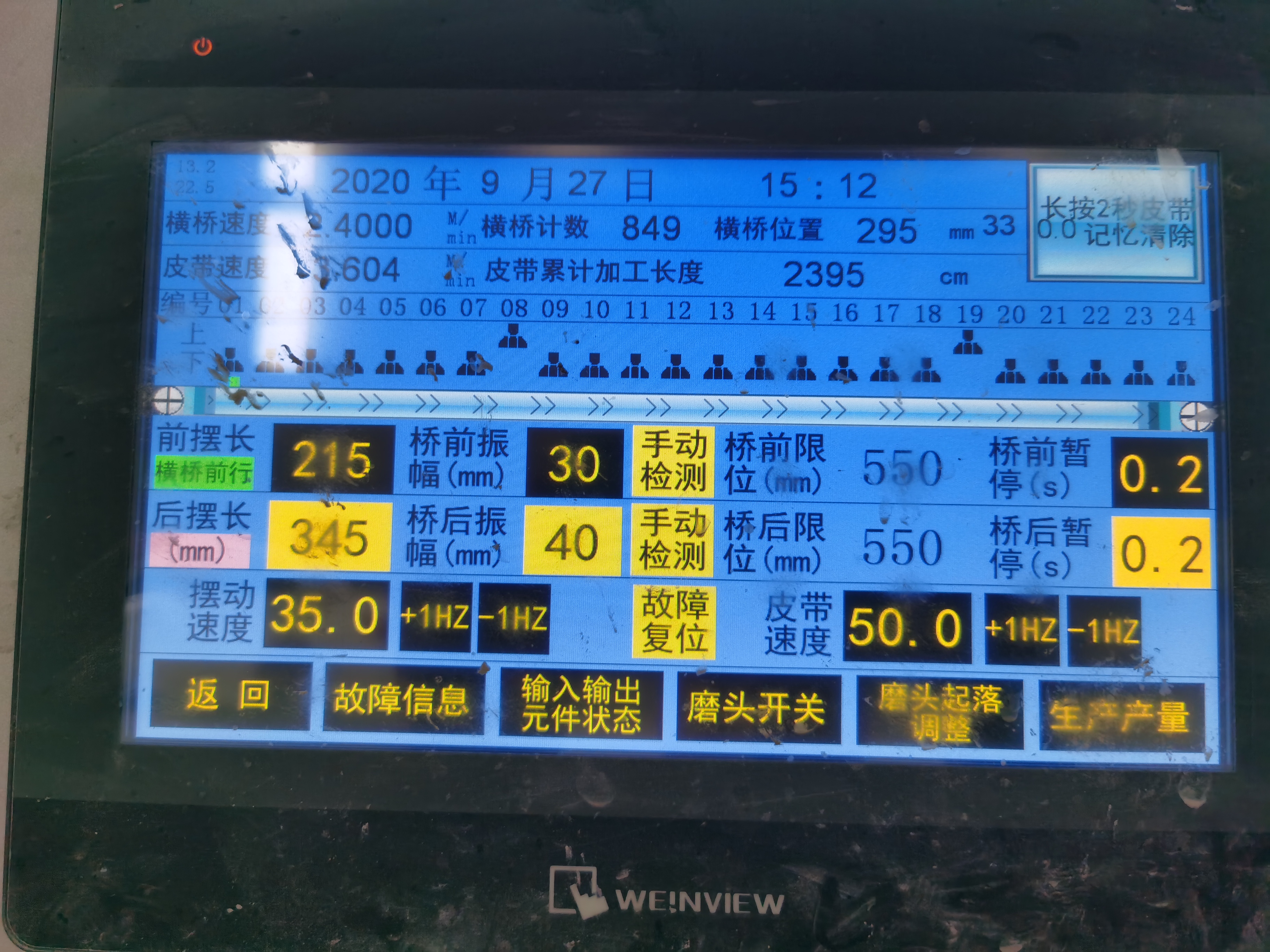

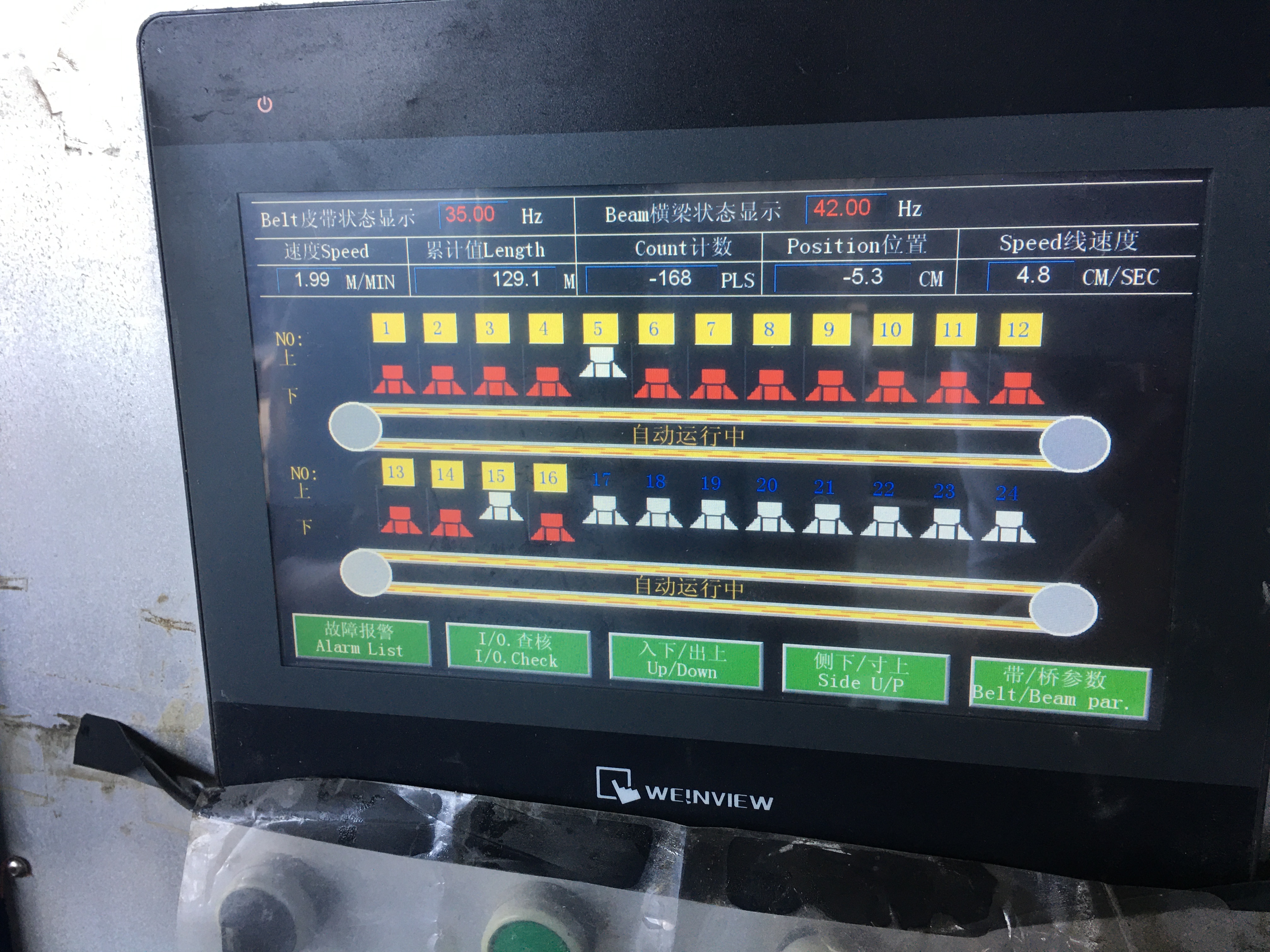

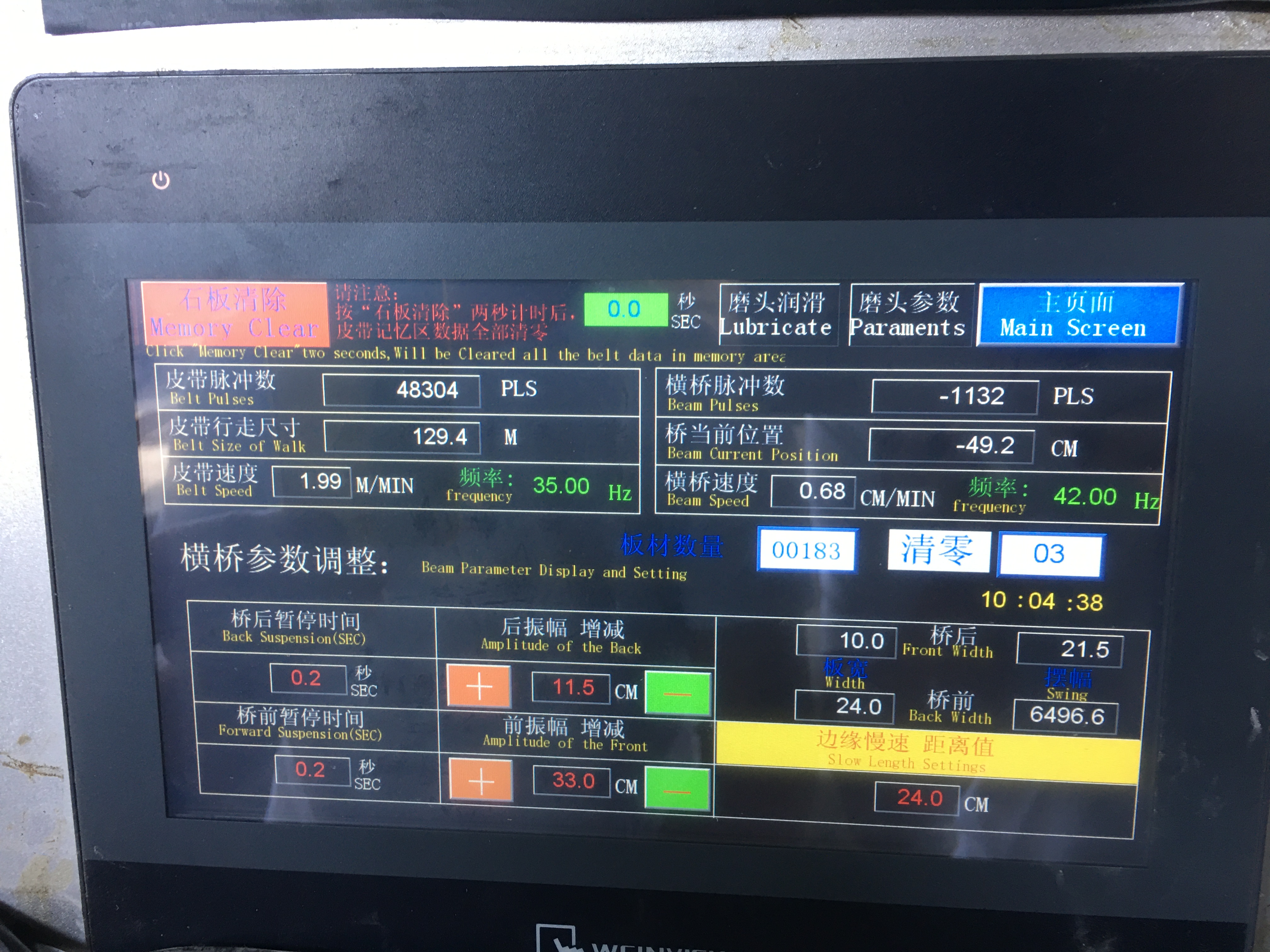

4. Advanced PLC Control and User-Friendly Interface

The automatic granite polishing machine uses a PLC control system with an LCD touch screen. Operators can:

- Set and adjust polishing parameters for different granite types

- Monitor the working status of each polishing head and conveyor in real time

- Receive troubleshooting tips and alarms when abnormal conditions occur

- Benefit from an automatic lubricating reminder system that helps protect key components

The human–machine interface is simple to understand, reducing training time and helping new operators quickly become productive.

5.Optimized Slab Handling and Drying

The complete line can include an automatic flap frame, automatic slab loading device, blow-dry unit and transition frames. These devices automate the transfer and drying of slabs before and after polishing, minimizing manual handling and reducing the risk of damage.

By automating slab loading and unloading, the polishing heads can work continuously, which directly increases the square meters processed per shift.

.jpg)

6. Flexible Speed and Pressure Control

The conveyor belt for the slabs and the movement of the transverse beam are controlled by frequency converters. This allows precise adjustment of the working speed according to:

- Granite hardness and structure

- Desired surface finish and gloss level

- Production capacity requirements

The working pressure of the polishing heads and the grinding width of the slabs can also be set within predefined limits. The machine can automatically identify slab shape and adjust the lifting of polishing heads accordingly. This means better polishing quality with less manual fine-tuning.

7. Advanced Spindle Lifting Structure

The spindle system adopts an advanced sliding sleeve lifting structure. This design improves stability during vertical movement, reduces vibration and helps maintain consistent contact between the abrasives and the granite surface. As a result, the machine can achieve excellent flatness and gloss, even at high working speeds.

8. Labor and Energy Savings

Because the process is automated and easy to control, one operator can manage a long granite polishing line. Compared with manual or semi-automatic polishing, factories can:

- Reduce the number of workers on the line

- Lower the cost per square meter of polished granite

- Use energy more efficiently thanks to frequency-controlled motors and optimized working speeds

Practical Tips for Stone Processors Considering an Automatic Granite Polishing Machine

When planning to upgrade your stone factory with an automatic granite polishing machine, consider the following points:

- Required production capacity in square meters per day or per month

- Available workshop space, power supply and water treatment conditions

- Types and sizes of granite slabs you process most frequently

- Preferred level of automation for loading, unloading and drying

- After-sales service, spare parts supply and technical support from the manufacturer

Choosing a reliable supplier with strong engineering capability and real project experience will help you avoid costly mistakes and achieve faster payback on your investment.

About Shuinan Machinery

Shuinan Machinery (Quanzhou Hiende Mechanical and Electrical Technology Development Co., Ltd.) has been engaged in stone mining and processing equipment since 1997. Located in Shuitou, China’s stone capital, the company operates a modern factory with advanced machining equipment, warehousing and assembly lines dedicated to stone machinery.

The company has passed ISO9001:2015 quality management certification, as well as CE and TUV safety certifications. With stable quality and professional service, Shuinan Machinery’s products – including automatic granite polishing machines, bridge cutting machines, diamond wire saws and other stone processing equipment – are exported to more than 30 countries and regions.

Contact Shuinan Machinery

If you are planning to upgrade your stone factory with an automatic granite polishing machine or a complete granite polishing line, Shuinan Machinery is ready to provide technical consultation, layout suggestions and detailed quotations.

You can contact us directly on WhatsApp by clicking the number below:

-1060x400w.jpg)

Leave a Comment